The role of Bending in the Aluminum Extrusion Industry

In the aluminum extrusion industry, bending as an important processing method, its role is mainly reflected in the following aspects:

Change the shape and structure of aluminum extrusion:

Bending technology can change aluminum extrusion products from straight shape to curved or specific angular shape to meet diversified design needs.

Through bending, turned aluminum can be used in more fields, such as architectural decoration, furniture manufacturing, machinery manufacturing, etc., providing greater design flexibility for products.

Increase the stiffness and strength of aluminum:

Bending creates a curved area at the bottom, a structure that enhances the stiffness and strength of the material.

Bent aluminum extrusions provide more reliable structural support where higher external pressures or loads are required.

Material and cost savings:

Bending technology allows a longer piece of aluminum profile to be machined into multiple sections of varying lengths to accommodate different design requirements.

This method not only avoids material waste, but also reduces production costs and improves economic efficiency.

Improve production efficiency:

Bending technology can realize automation and mechanization of production, significantly improving production efficiency.

Bending equipment can accurately and quickly complete the aluminum extrusion bending process, shorten the production cycle to meet the needs of mass production.

Change the appearance of the product:

Bending can give a product a curvier, more streamlined shape, making it more aesthetically pleasing to the eye.

In areas that require attention to the quality of appearance, such as automobiles, home appliances, etc. Aluminum extrusion can enhance the overall aesthetics and market competitiveness of the product.

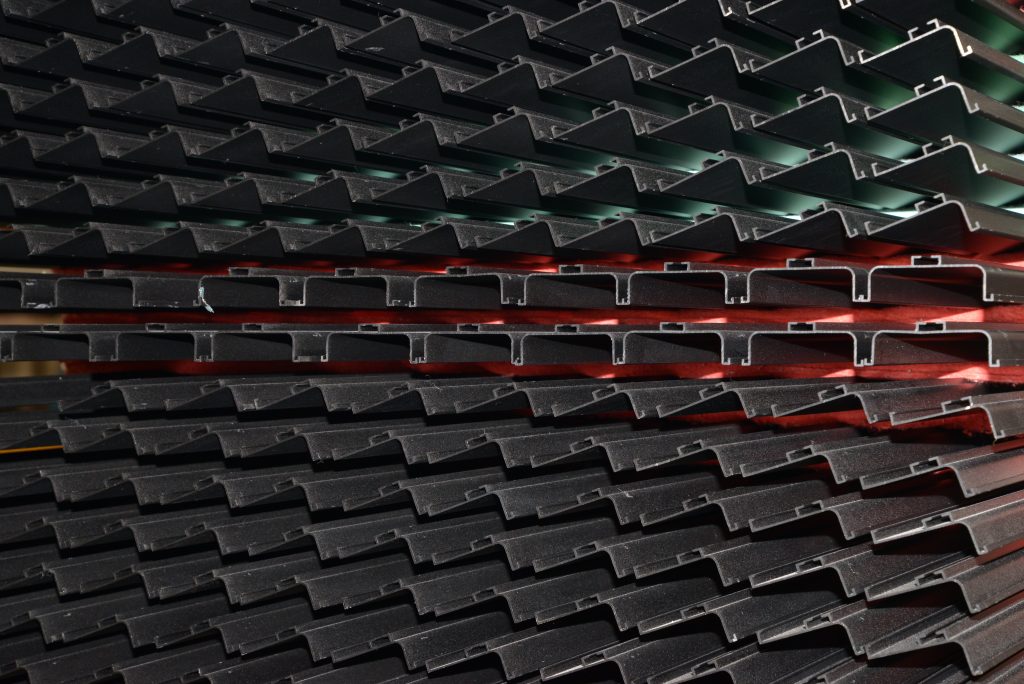

What aluminum extrusion products need bending?

Round tubular aluminum:

Round tubular aluminum has a round cross-section and does not have an obvious flare when bending, making it ideal for round bending. This type of bent aluminum tube is commonly used to make furniture, display racks, lighting, and other products that require a specific curved shape.

Equilateral angle aluminum profiles:

Equilateral angle aluminum profiles have a square or rectangular cross-section with an equal number of four angles, and are often used to make frames, doors, windows, and other structures. In order to stabilize the frame, bending is required to achieve the installation effect.

In summary

Bending plays a vital role in the aluminum extrusion industry. It not only changes the shape and structure of aluminum profiles and increases the stiffness and strength of the products, but also saves materials and costs, increases production efficiency, and improves the appearance of the products.

Hugh Aluminum is an aluminum extrusion plant located in China. We have machining capacity for aluminum extrusion, aluminum bending and surface treatment. We are able to provide from design to manufacturing.

If you need to purchase aluminum products in bulk or looking for quality suppliers? Please contact us!