What are the Benefits of Choosing Extruded Aluminum?

Aluminum extrusion molding is placed in the die cavity (or extrusion cylinder) within the aluminum billet to exert strong pressure, forcing the aluminum billet to produce directional plastic deformation, extrusion from the extrusion die hole, so as to obtain the required cross-section shape, size and have certain mechanical properties of the parts or semi-finished plastic processing methods.

Here is the video of extrusion from Hugh Aluminum:

Then the benefits of using the choice of extruded aluminum are as follows:

1.Long lasting and durable aluminum profiles

Aluminum’s resistance to corrosion, erosion and weathering is one of its most notable benefits. Aluminum is naturally rust and corrosion resistant without any additional treatment. This is due to the presence of a thin, naturally occurring protective film of aluminum oxide on its surface. By anodizing, its resistance to corrosion becomes even stronger.

For example, in outdoor environments, anodizing can be performed to 25 microns, which enhances both corrosion resistance and surface finish. In addition, aluminum does not require maintenance, and in most cases you can not worry about corrosion.

2. Lightweight and strong

Aluminum is over 33% lighter than steel while retaining most of its strength. Most aluminum alloys have a tensile strength range of about 70-700 MPa, while being two-thirds less dense than steel.

Product design engineers do not have to worry about the strength of aluminum extruded parts, which can be used as structural components in the construction and automotive industries alike, making it an excellent alternative to other metal materials. In order to lightweight and reduce energy consumption, the automotive industry is using aluminum alloy significantly!

3. Good thermal conductivity

Aluminum’s thermal conductivity is very similar to that of copper, but it is much lighter. Aluminum is an excellent thermal conductor, and the contours of the aluminum extrusion are designed to maximize the surface area for thermal conductivity and the formation of thermal channels. A typical example is a computer CPU cooler, where aluminum is used to carry heat away from the CPU.

4. Fashionable appearance

Extruded aluminum can be painted, plated, polished, and anodized, which gives engineers a wider range of appearance options than other materials.

5. Wide range of applications

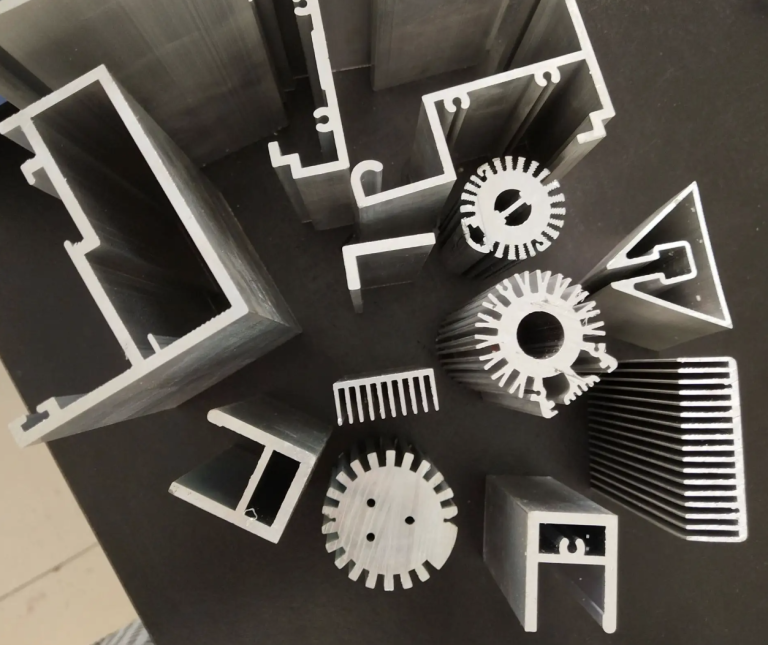

Basically any cross-section shape can be formed by aluminum extrusion, so aluminum extrusion has a very wide range of applications, engineers can design different sections to meet the requirements of different application environments

6. Easy secondary processing

Aluminum extrusions can be easily formed, cut, drilled, machined, stamped, bent and welded to suit specific purposes. Builders can use extruded aluminum for secondary processing to meet the requirements of building materials. Examples include windows, doors, decks, railings and curtain walls.

Finally, there are many benefits to choosing extrusion. It encompasses: durability and longevity, ease of machining, wide range of applications, lightweight strength, stylish appearance and easy secondary processing. These benefits have made it a major material in the aluminum market.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including aluminum heat sink, aluminum T-slot profile, aluminum deck, aluminum fence, aluminum doors and windows and aluminum roofings, solar aluminum frame. We offer large quantity of aluminum building materials and factory price.