What are the Benefits of Welded Aluminum Fence?

Welded aluminum fences have so many benefits for homeowners and businesses. These fences are strong, beautiful, and practical for boundary and security. Aluminum fences are durable and lightweight compared to many other fencing materials.

This guide will explore the benefits of welded aluminum fences. We’ll look at durability, low maintenance, design options, and cost. If you want to improve your property’s security, appearance or outdoor space, a welded aluminum fence might be the answer.

Related products: Aluminum fence panels

What is a Welded Aluminum Fence?

Welded aluminum fences are a type of fencing where the aluminum parts are welded together. This creates a solid bond between the fence rails and pickets so it’s durable and long-lasting.

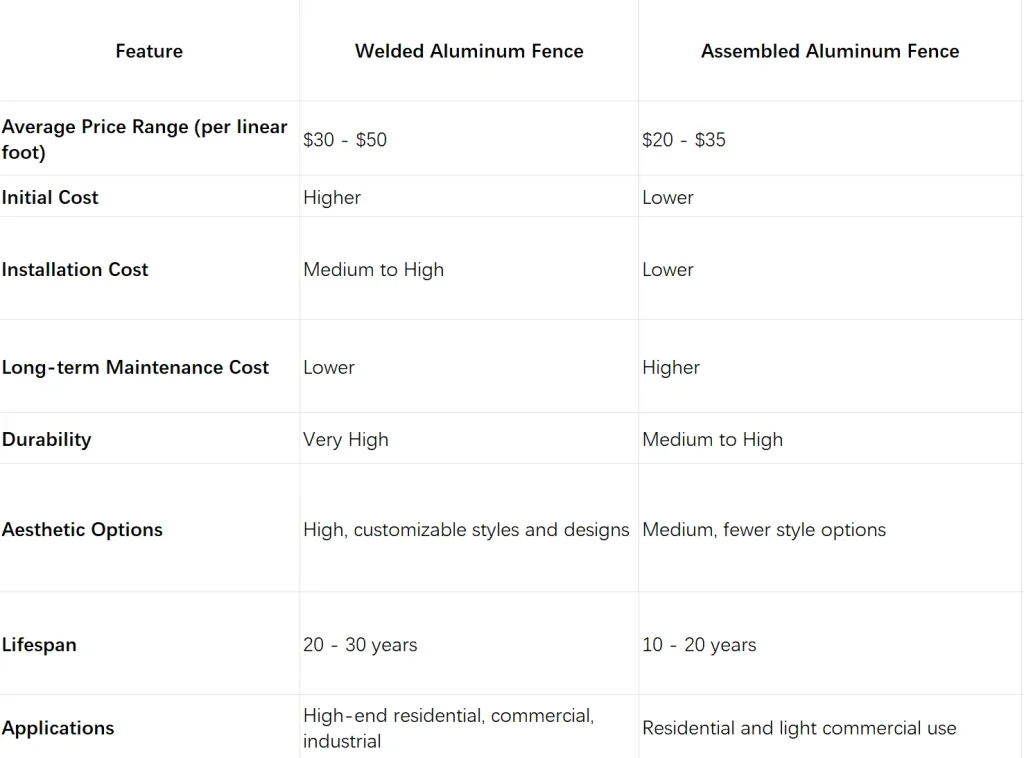

Other aluminum fences are assembled with bolts or screws, welded fences are fabricated in panels with each joint welded. This makes them stronger and more stable than other types of aluminum fences or fences made of other materials.

The welding process used in these fences produces a seamless rigid fence which is favored by housing contractors. Putting a welded aluminum fence in your backyard or apartment balcony can protect your property.

Compared to assembled aluminum fences, welded fences are sturdier and more secure. They won’t loosen or come apart over time so your fence will remain in top condition for years to come. This is perfect for homeowners and contractors who want a reliable quality fencing solution.

Welded Aluminum Fence Structures

Welded aluminum fences have three main components:

Rails: These are the horizontal bars that make up the top, middle, and bottom of the fence panel. Residential fences use rails that are 1.5 to 2.5 inches thick, industrial fences use rails up to 4 inches thick.

Pickets: The vertical bars attached to the rails are the main barrier. Residential fences have pickets 3 to 4 inches apart, and security fences have pickets closer together. Picket styles are spear tops, flat tops, and custom decorative ends.

Posts: These are the vertical supports that hold the fence panels in place. Posts are 2 to 3 inches thick and are set in concrete or mounted with brackets.

Gates: Welded aluminum gates are part of the overall fencing system. These gates have welded hinges and reinforced frames. Commercial and industrial applications may have locks and automated openers for added security.

These all work together to make a strong, beautiful, and customizable fence. Whether you want to dress up your home or secure an industrial site, welded aluminum fences have the solution.

Welded Aluminum Fencing Benefits

Durability and Strength

Welded aluminum fences have strong joints. Stronger than wood or vinyl fences. No rivets or bolts to loosen over time.

Aluminum forms a natural protective layer that prevents rust. Fences last for decades in heavy rain or salty coastal air. Powder coating adds another layer of protection. Fences last 20-30 years with minimal maintenance.

Low Maintenance

Aluminum is easy to clean – soap and water. No staining, painting, or sealing. Over 10 years aluminum fences cost 60% less to maintain than wood fences.

Lightweight and Easy Installation

Aluminum is lighter than steel or iron. Faster and cheaper to install. Pre-assembled welded panels go up quickly. Aluminum is light enough for custom designs like curves or intricate patterns without sacrificing stability.

Aesthetic Appeal and Versatility

Aluminum fences come in many styles – modern to traditional. Mimic wrought iron at a lower cost. Powder coating enhances appearance and finish lasts 15 years longer than paint. Aluminum fences adapt to any architectural style – flat-top, spear-top, decorative.

Environmental Friendly

Aluminum is highly recyclable – 75% of all aluminum ever produced is still in use. Recycling aluminum uses 95% less energy than making new aluminum. It’s eco-friendly.

Security and Safety

Welded aluminum fences are hard to breach. Withstand winds up to 150 mph. Good for the hurricane or severe weather areas.

Cost Effective

While more expensive upfront than some materials, aluminum fences offer long-term savings in maintenance and longevity. Cheaper than wrought iron with a similar aesthetic and strength.

Conclusion

Welded aluminum fencing gives you practical and aesthetic benefits. Security, style, and sustainability in one. If you’re looking for a reliable fencing solution welded aluminum is the smart choice.

Remember, good fences make good neighbors, but great fences make your property the talk of the town. Welded aluminum fencing might just be your ticket to fame – without the paparazzi.