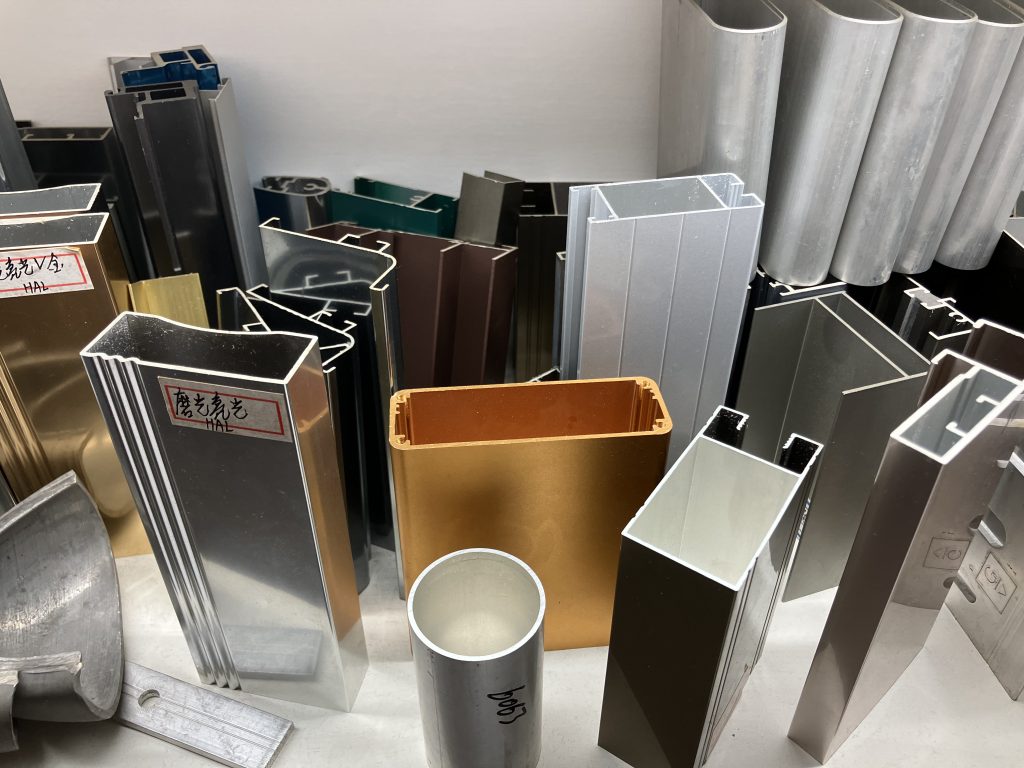

What factors affect the durability of Aluminum Extrusions?

The factors affecting the durability of aluminum extrusions can be summarised as follows:

1. Aluminum extrusions material:

The material quality and proportion of aluminum extrusions have a direct impact on the life span. Good material and a reasonable proportion of aluminum alloy have higher corrosion resistance and oxidation resistance, and therefore the life is relatively longer.

For example, aluminum alloy 6063-T5 or 6061-T6 aluminum alloy. Their service life is good.

2. Manufacturing and processing:

Aluminum extrusions in the process of processing technology level and processing technology will also affect life. The machining precision and the good or bad surface treatment will affect its durability.

If the manufacturing precision fails to meet the quality requirements. The tolerance is larger than the design requirements, or the product design is unreasonable.

These will shorten its service life. It may even be dangerous to use. Therefore, it is necessary to choose a high quality aluminium extrusion factory.

3. Its Design:

The design of aluminum extrusion has an important influence on its durability. Reasonable design can avoid problems such as stress concentration and fatigue and improve its service life.

An example is the double-layer structure of aluminum doors and windows. It has the advantages of good heat preservation and insulation, good drainage performance, good fire resistance, etc., and has a relatively long service life.

The ordinary structure of aluminum alloy doors and windows has a relatively short service life due to its poor performance.

4. Use environment:

The use environment of aluminium extrusion mainly includes temperature, humidity, chemical substances, mechanical vibration and other factors. The environment that is easy to corrode and the parts that are frequently subjected to impact may directly affect the service life of aluminium extrusions.

Aluminium is easy to shorten its service life when it is in a harsh environment such as humidity, corrosion and high temperature for a long time.

5. Maintenance:

Aluminium extrusions also requires proper maintenance during use. Otherwise, aluminium extrusion is prone to friction, wear and tear and other problems during use, thus affecting the service life.

We can carry out regular cleaning, maintenance and repair. This can avoid the erosion of pollution and acid on aluminium and reduce wear and damage.

In summary, the durability of aluminum profiles is jointly affected by many factors. In practical application, these factors need to be considered comprehensively, and only reasonable use can make its service life longer.

Hugh Aluminum is an aluminum extrusion plant. We offer a design-to-production service. We have 14 years of production experience and have served over 600 customers from 40 countries.

If you want to purchase aluminum extrusion products in bulk or looking for a good supplier.

Please contact us!