What is 1060 Aluminum Alloy?

Manufacturers widely use 1060 aluminum alloy in everyday products. Items like kitchenware and clocks often feature this material because of its durability and versatility.

So, what sets this alloy apart? Let’s take a closer look at its properties and why it’s such a popular choice for various applications.

What Elements Make Up the 1060 Aluminum Alloy?

1060 aluminum alloy contains at least 99.6% aluminum, making it one of the purest aluminum alloys available. Alongside aluminum, it includes small amounts of other elements that slightly affect its properties.

Iron (Fe) is present at less than 0.35%, while silicon (Si) contributes less than 0.25%. Copper (Cu) is limited to less than 0.05%, and manganese (Mn) is capped at less than 0.03%. Although these elements are present in tiny amounts, they influence characteristics like strength and durability.

This composition ensures that 1060 aluminum maintains its high purity while benefiting from subtle enhancements provided by these trace elements.

Properties of 1060 Aluminum Alloy

1. Density

The density of 1060 aluminum is approximately 2.7 g/cm³. This lightweight property makes it suitable for applications where reducing weight is important, such as in transportation and packaging.

2. Coefficient of Thermal Expansion

1060 alloy has a thermal expansion coefficient of 23.5 x 10⁻⁶/K. This means it expands or contracts minimally with temperature changes, reducing the risk of deformation or cracking in heat-sensitive environments.

3. Thermal Conductivity

The thermal conductivity of 1060 alloy is 235 W/(m-K). It efficiently transfers heat, making it ideal for applications requiring effective heat dissipation, such as cooling systems and industrial equipment.

Mechanical Properties

- Strength: 1060 aluminum has a yield strength of 65 MPa and a tensile strength between 110 and 136 MPa. It performs well under moderate stress, making it suitable for applications where high strength is not critical.

- Hardness: Its hardness measures 16-18 HB on the Brinell scale. This low hardness means the alloy is soft and easy to shape, ideal for processes like bending and forming.

- Elongation: The alloy has excellent elongation properties, allowing it to stretch significantly without breaking. This flexibility makes it a practical choice for projects requiring high plasticity, such as creating thin sheets or complex shapes.

How Does 1060 Aluminum Alloy Perform in Machining?

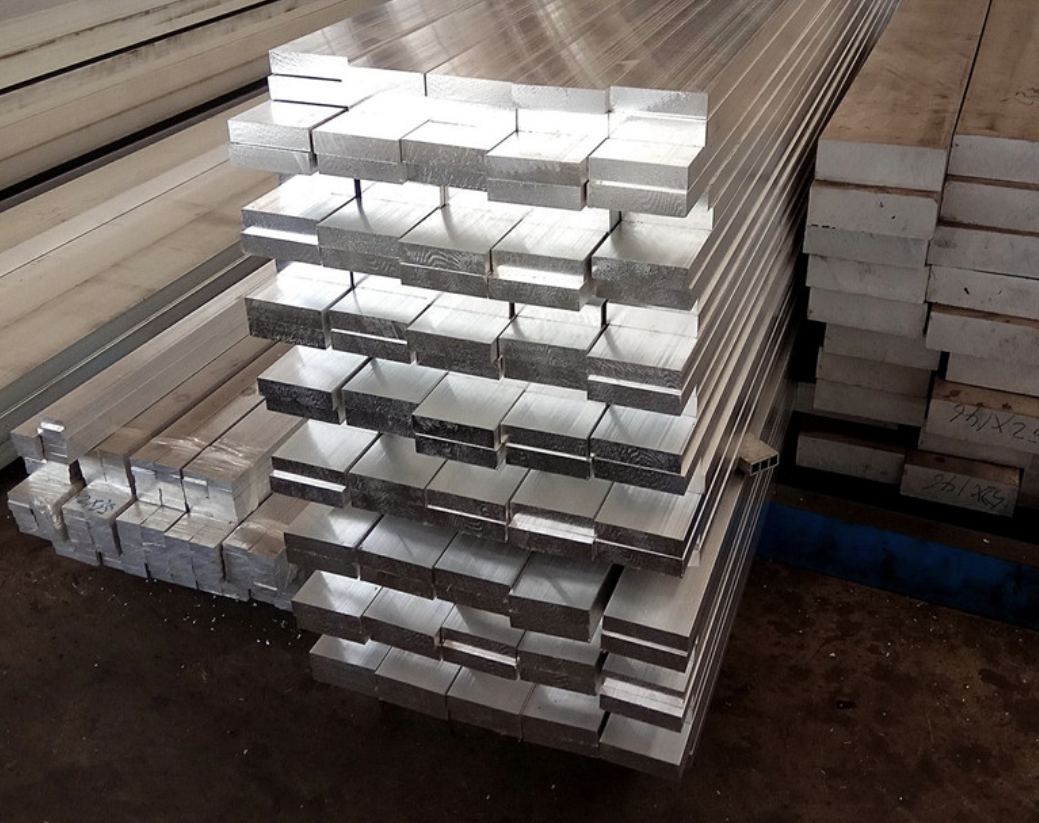

1060 aluminum is easy to process using various methods. It can be rolled, stretched, sheared, die-cast, or cold forged. Its high purity ensures stable and reliable performance during machining, making it a practical choice for industries that need consistent results.

Why 1060 Aluminum Alloy Excels in Corrosion Resistance?

This alloy resists corrosion from most common chemicals and avoids oxidation, rust, and degradation. Its durability makes it ideal for ships, marine equipment, and chemical machinery. Manufacturers rely on this material in environments exposed to moisture or harsh substances.

Uses of 1060 Aluminum Alloy:

1060 aluminum is commonly used for products that require flexibility but not high strength. It is ideal for chemical instruments and thin plates, offering reliable performance in manufacturing. This alloy works well for deep drawing and spinning processes, making it suitable for concave utensils.

It is also used in welded parts, heat exchangers, clock faces, and plates. Nameplates, kitchen tools, and decorative items often feature this material due to its adaptability. Additionally, its reflective properties make it a popular choice for appliances that need a polished finish.

Related products: Extruded aluminum profiles

Final Thoughts

1060 aluminum alloy is a high-purity material with practical advantages. It is lightweight, which makes it easy to work with, and it offers excellent thermal conductivity.

These properties make it useful in various industries, including chemical processing, electronics, and automotive manufacturing. Its reliability and versatility ensure it remains a popular choice for many applications.