What is 5000 Series Aluminum? Everything You Need to Know

5000 series aluminum is a strong and lightweight alloy made by combining aluminum with magnesium and other metals. It is widely used because of its durability and versatility.

This alloy resists corrosion, making it ideal for marine environments. It is also easy to shape, which makes it useful for applications that require flexibility without sacrificing strength. Industries like construction and transportation rely on 5000 series aluminum for its reliable performance.

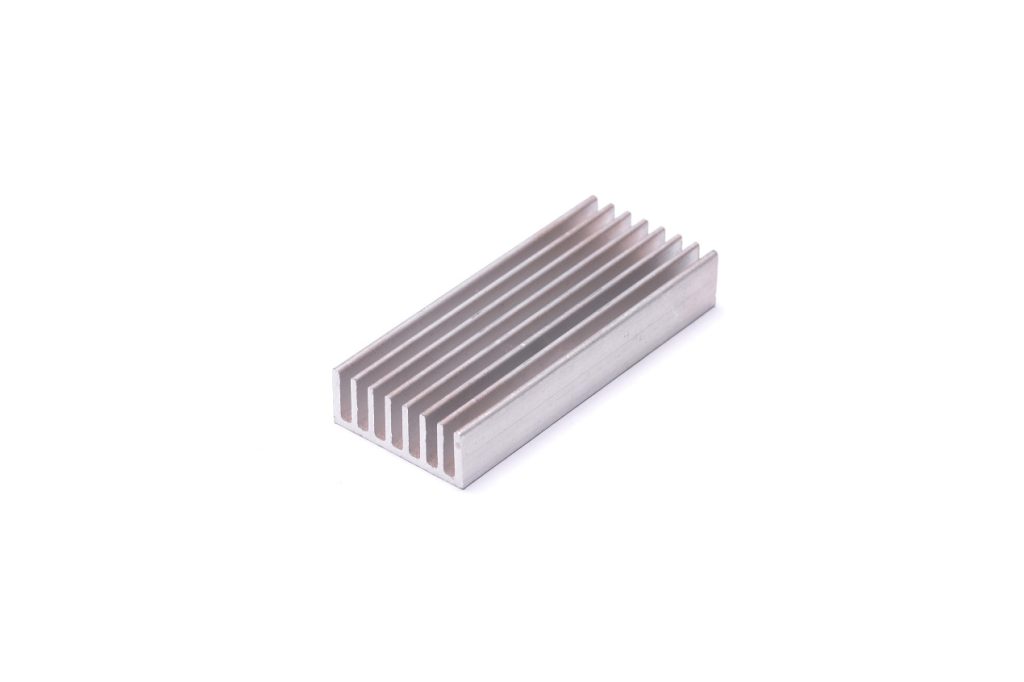

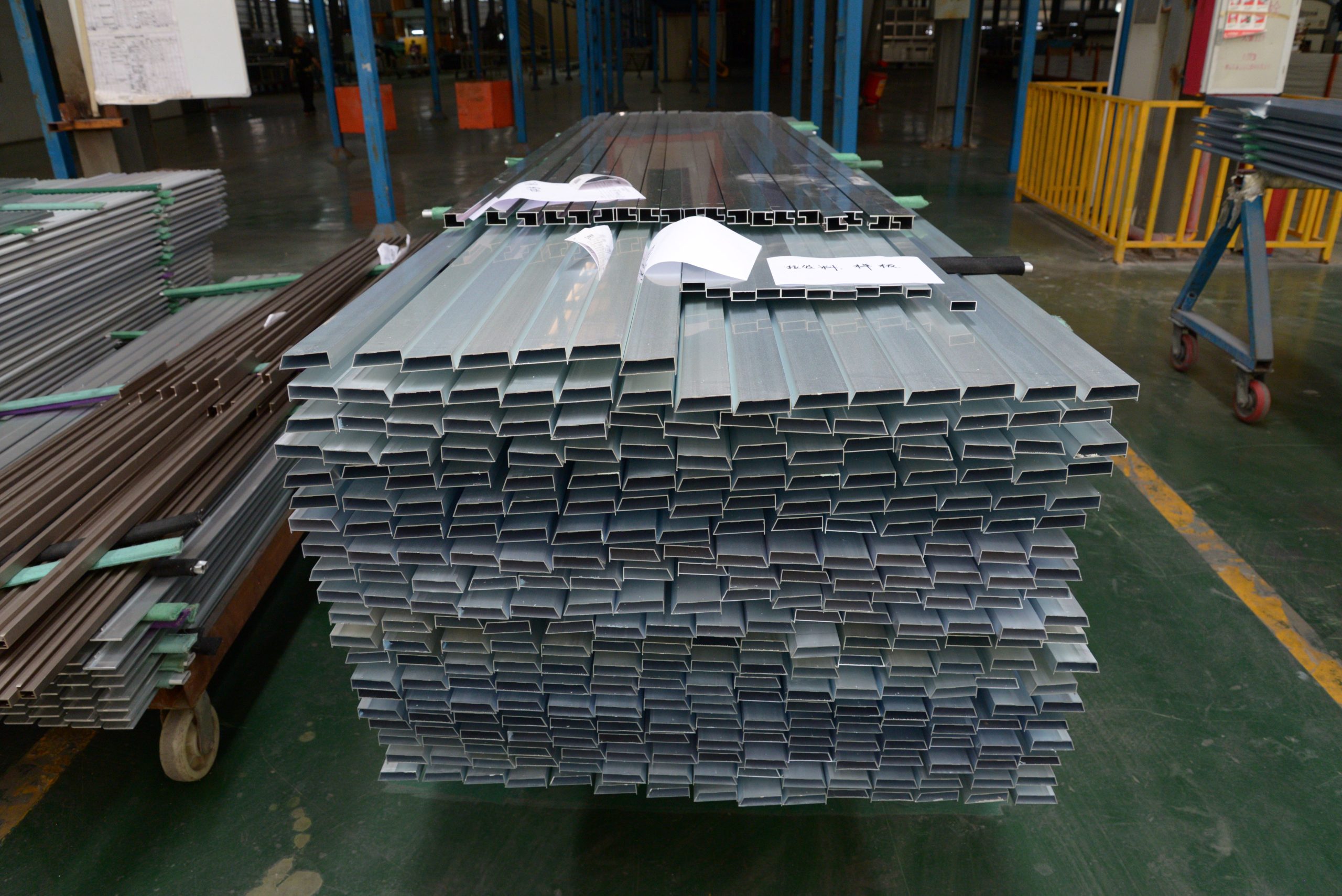

Related products: Extruded aluminum profiles

What Is the Metal Composition of 5000 Series Aluminum?

5000 series aluminum is made of aluminum combined with magnesium. The magnesium content typically ranges from 3% to 5%, which enhances the alloy’s strength and resistance to corrosion.

For instance, 5052 aluminum contains about 2.5% magnesium, while 5083 aluminum has a higher magnesium content, between 4.0% and 4.9%.

This carefully balanced composition gives the alloy its durability and makes it suitable for various applications where reliability is essential.

5xxx Aluminum Series Physical Properties

Strength

The 5000 series aluminum is known for its high tensile strength. It is suitable for applications that require durability and resistance to heavy loads. Certain grades, such as 5052 aluminum alloy, also offer good fatigue strength, making them ideal for environments with repeated stress or cyclic loads.

Corrosion Resistance

These alloys perform exceptionally well in corrosive environments, including exposure to seawater and chlorides. Their corrosion resistance improves further when the magnesium content is within a specific range. This makes them a reliable choice for marine and industrial applications.

Machinability

5000 series aluminum is easy to shape and process into various forms and sizes. It has excellent forming capabilities, making it practical for manufacturing diverse components. Cold-working certain grades, such as 5052 aluminum alloy, enhances their strength and adds versatility to their applications.

Weldability

The 5000 series aluminum alloys are highly weldable. Grades like 5083 and 5086 are particularly effective for welding projects, making them suitable for applications such as shipbuilding, storage tanks, and structural components.

These physical properties—strength, corrosion resistance, machinability, and weldability—make the 5000 series aluminum a versatile material for industries like marine engineering, automotive manufacturing, and construction. Its reliability ensures it can handle demanding environments with ease.

Key Features of Grade 5083 Aluminum Alloy

Grade 5083 aluminum alloy offers exceptional strength, corrosion resistance, and versatility. Industries like marine construction and transportation rely on it for its reliable performance.

Strength

5083 aluminum alloy has a high tensile strength of at least 270 MPa. This makes it one of the strongest alloys in the 5000 series, capable of handling heavy loads and demanding applications.

Corrosion Resistance

This alloy offers excellent resistance to corrosion, especially in saltwater environments. Its durability makes it ideal for ships, offshore platforms, and other marine structures.

Machinability

5083 aluminum alloy can be easily machined into various shapes and sizes. Its composition allows manufacturers to create precise parts without compromising its structural integrity.

Anodizing Treatment

After anodizing, the surface of 5083 aluminum alloy becomes more resistant to corrosion and gains a visually appealing finish. This process enhances its suitability for decorative and protective applications.

Welding Performance

5083 aluminum alloy supports common welding methods such as argon arc welding, MIG welding, and TIG welding. It maintains its strength after welding, making it a practical choice for projects requiring strong joints.

This alloy stands out for its balance of strength, durability, and adaptability, making it a trusted option across multiple industries.

The composition table of 5083 aluminum alloy:

| Elemental | Content range(%) |

|---|---|

| aluminum (Al) | Usually around 97.6% |

| Manganese (Mn) | ≤0.40% |

| copper (Cu) | ≤0.10% |

| magnesium(Mg) | 4.0~4.9% |

| zinc (Zn) | ≤0.25% |

| Zinc (Zn) | 0.40~1.0% |

| titanium (Ti) | ≤0.15% |

| chrome (Cr) | 0.05~0.25% |

| iron (Fe) | 0.000~0.400% |

Key Features of Grade 5754 Aluminum Alloy

Manufacturers widely use the 5754 aluminum alloy from the 5000 series due to its strength, corrosion resistance, and adaptability. Below are its key features:

Corrosion Resistance

5754 aluminum resists damage from seawater and chlorides. This makes it ideal for offshore structures, oilfield equipment, and other environments exposed to moisture and salt.

Medium Strength

This alloy offers moderate strength, making it suitable for many engineering applications.

Strength Potential

With heat treatment, 5754 aluminum can achieve higher strength levels, expanding its range of uses.

Toughness and Flexibility

The alloy handles heavy mechanical stress while remaining easy to shape during processing. This combination makes it a preferred material for submarine pipelines and other demanding applications.

5754 aluminum alloy is a practical choice for projects requiring durability, corrosion resistance, and adaptability. It performs well in tough conditions while remaining versatile enough for various industries.

The Chemical composition table of Grade 5754:

| Silicon (Si) | Content range(%) |

|---|---|

| aluminum (Al) | around 96% |

| Manganese (Mn) | ≤0.40 |

| copper (Cu) | ≤0.10 |

| magnesium(Mg) | 2.6~3.6 |

| titanium (Ti) | ≤0.15 |

| Zinc (Zn) | ≤0.20 |

| manganese (Mn) | ≤0.50 |

| chrome (Cr) | ≤0.30 |

The Key Features of Grade 5251 Aluminum

Grade 5251 aluminum is a popular alloy in the 5000 series. It is known for its strength, corrosion resistance, and ease of processing. Here are its main features:

Strength

5251 aluminum has good tensile and yield strength. It is strong enough to support structural components in various industries.

Corrosion Resistance

This alloy resists oxidation and damage from corrosive elements. It performs well in wet environments and marine applications.

Weldability and Formability

5251 aluminum is easy to weld and shape. It can be processed in cold conditions but hardens quickly during fabrication, requiring careful handling.

Grade 5251 aluminum is a durable and versatile material. Its combination of strength, corrosion resistance, and workability makes it suitable for applications like marine engineering, automotive parts, and storage tanks.

The Chemical Composition Table of Grade 5251:

| Silicon (Si) | Content range(%) |

|---|---|

| aluminum (Al) | around 97.5% |

| Magnesium (Mg) | ≤0.40 |

| copper (Cu) | ≤0.10 |

| Manganese (Mn) | 3.5~4.5 |

| Zinc (Zn) | ≤0.25 |

| manganese (Mn) | 0.20~0.7 |

| titanium (Ti) | ≤0.15 |

| chrome (Cr) | 0.05~0.25 |

| iron (Fe) | 0.000~0.500 |

Applications of 5000 Series Aluminum Products

5000 series aluminum alloys play a crucial role across industries due to their strength, corrosion resistance, and lightweight properties. Below are their key applications:

Aircraft Manufacturing

Manufacturers use 5000 series aluminum to construct aircraft fuselages, wings, and other components. Its low weight and high strength make it ideal for aviation parts that demand durability without adding unnecessary mass.

Spacecraft Components

Aerospace engineers rely on these alloys for rockets and satellites. They deliver the necessary strength while keeping the overall weight minimal.

Automotive Manufacturing

Automakers incorporate 5000 series aluminum into body panels, engines, and transmission systems to reduce vehicle weight and enhance efficiency. Alloys like 5083 and 5052 stand out as popular choices for these applications.

Shipbuilding

5000 series aluminum is ideal for marine environments. Its corrosion resistance makes it a reliable material for hulls, decks, and other ship components exposed to water and salt.

These alloys combine strength, corrosion resistance, and lightness to meet the demands of industries like aviation, aerospace, automotive, and marine engineering. Their versatility makes them a valuable material for modern manufacturing needs.