What is 5754 Aluminum Extrusion?

5754 aluminum extrusion is a durable material made from aluminum and magnesium. Its composition includes at least 93.8% aluminum and up to 1.6% magnesium.

This specific blend gives the alloy strength and resistance to corrosion, making it suitable for demanding environments. It performs well in industries like automotive and marine, where materials must withstand tough conditions.

Known for its reliability, 5754 aluminum is often chosen for applications that require both durability and flexibility. It handles stress without breaking down, making it a trusted option for many projects.

Related products: Extruded aluminum profiles

Advantages of 5754 Aluminum Extrusions

Excellent Corrosion Resistance

5754 aluminum resists oxidation and corrosion extremely well. This makes it perfect for ships, coastal engineering, and other marine environments. It also stands up to common corrosive agents like gasoline, ethanol, and seawater.

Strong Performance

This aluminum has high tensile, yield, and flexural strength. It can handle heavy loads and impacts. For reference, 5754’s tensile strength is at least 280 MPa. Its yield strength is not less than 170 MPa, and it has an elongation of at least 10%.

Ease of Processing

You can easily shape and size 5754 aluminum profiles. Cut it, stamp it, draw it into deep shapes, or bend it. This makes it versatile for various applications from automobile parts to construction materials.

The extruded aluminum parts from 5754 alloy are a reliable choice for builders and engineers. Want to know more about its uses? Stick around!

Where Is 5754 Aluminum Extrusion Used?

Automobile Manufacturing

Manufacturers use 5754 alloy profiles in car doors, molds, and seals. It offers high strength and resists corrosion, meeting the demands of the automotive industry. Its ease of processing makes it a practical choice for manufacturers.

Shipbuilding

Extruded 5754 aluminum is essential for hull structures, ship plates, interiors, and fuel tanks. It provides durability and protection against corrosion, making it ideal for marine environments.

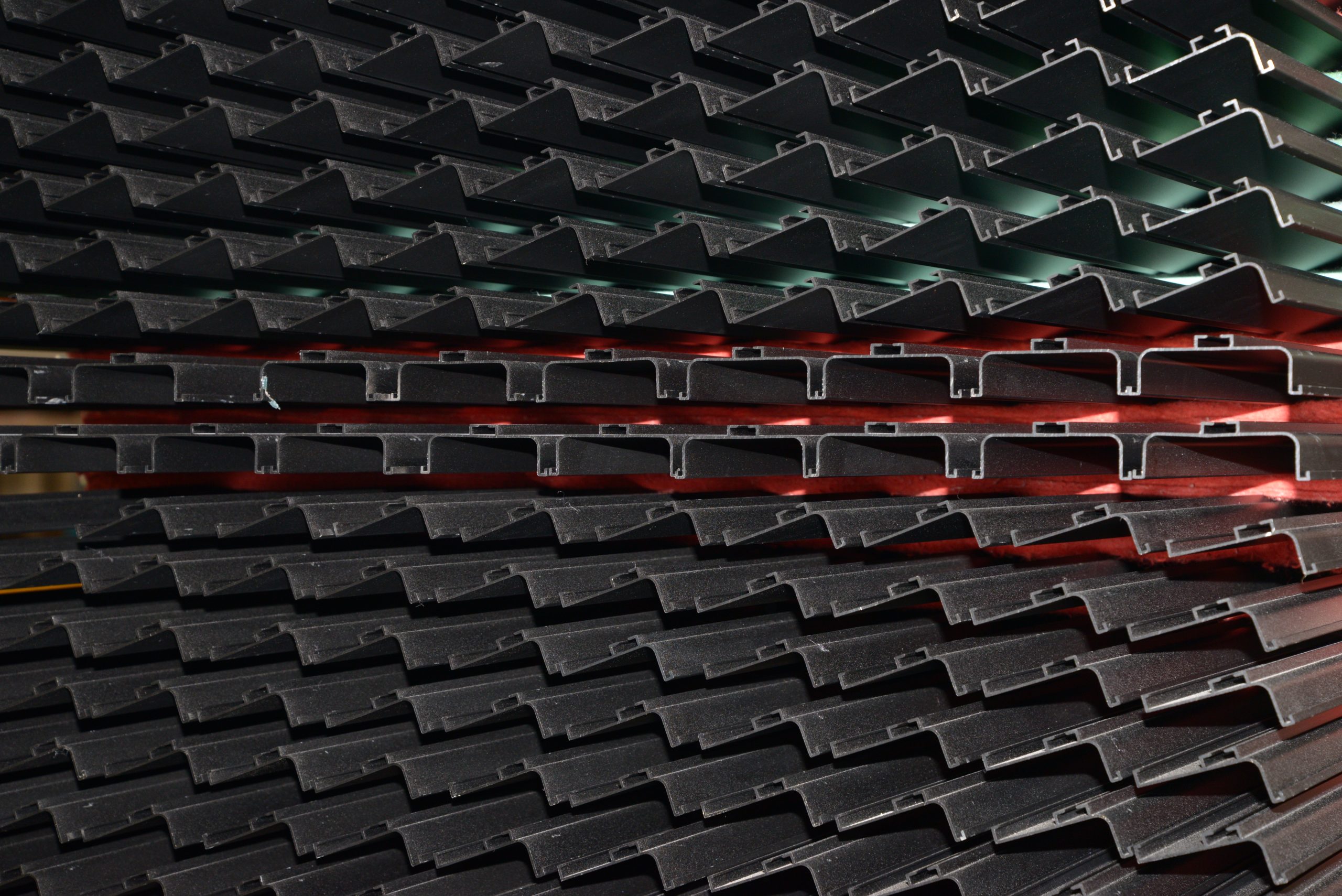

Construction

5754 aluminum is widely used in wall panels, roofing, window frames, and solar panel brackets. It delivers long-lasting performance while maintaining a clean and modern appearance.

How to Manufacture 5754 Aluminum Extrusions?

5754 aluminum is versatile and easy to shape. Manufacturers can weld, drill, stamp, or bend it to meet various needs. Manufacturers primarily use aluminum extrusion to form it into specific profiles.

This material supports surface treatments like oxidation, electroplating, and powder coating. These treatments improve its appearance and increase its resistance to corrosion and wear.

5754 alloy profile is ideal for vehicles, ships, and buildings. It offers strength, flexibility, and reliability for demanding applications.

Final Thoughts

The extruded 5754 aluminum is a versatile aluminum alloy. It performs well in various fields like automobiles, ships, and construction. If you need a strong and reliable material, choose 5754 aluminum profiles.