What is 6000 Series Aluminum Extrusion?

6000 series aluminum profile is a common aluminum alloy material for construction, and its main features and detailed information are as follows:

1. Overview

6000 Series Aluminum Profiles, also known as Al-Mg-Si Series Aluminum Alloys, is an aluminum alloy containing silicon and magnesium as the main alloying elements.

This series of aluminum alloy is widely used in many fields because of its good process performance, medium strength, high plasticity and corrosion resistance.

2. Metal Composition

The main components of 6000 series aluminum extrusion include aluminum (Al) magnesium (Mg) and silicon (Si). Among them, magnesium and silicon can form the main reinforcement Mg2Si, which provides strength and hardness to the alloy.

In addition, aluminum alloys in this series may contain small amounts of other alloying elements such as copper (Cu) and manganese (Mn) to further adjust their properties.

Characteristics of 6000 Series Aluminum

1. Density:

It has a relatively low density, usually between 2.6 and 2.8 g/cm³. This low density makes it ideal for many lightweight designs.

2. Strength:

It has high strength and is capable of achieving medium strength levels for aluminum alloys. This allows it to meet the needs of many applications. For example, 6061 aluminum alloy has high strength and good welding properties.

3. Corrosion resistance:

The 6000 series aluminum alloy has good corrosion resistance, especially to oxidation and corrosive environments. This allows it to maintain good performance in marine, wet and chemically corrosive environments.

4. Machinability:

The 6000 series aluminum extrusion has good machinability and is easy to be forged, extruded, stamped and welded. Especially 6063 aluminum alloy, it is a cold treatment forging products, easy to coating and processing.

5. Thermal conductivity:

The 6000 series aluminum alloy exhibits good thermal conductivity. This gives it an advantage in applications that require heat dissipation, such as electronic equipment and automotive engines.

6. Weldability:

6000 Series aluminum alloys have excellent weldability, especially 6061 aluminum alloys, and are easy to perform a variety of welding processes.

7. Acceptable anodizing:

6000 series aluminum profiles (especially 6xxx series aluminum alloy) are suitable for anodic oxidation treatment, which can form a protective oxide layer and further enhance its corrosion resistance.

Based on these characteristics, 6000 series aluminum profiles can play a role in the following areas.

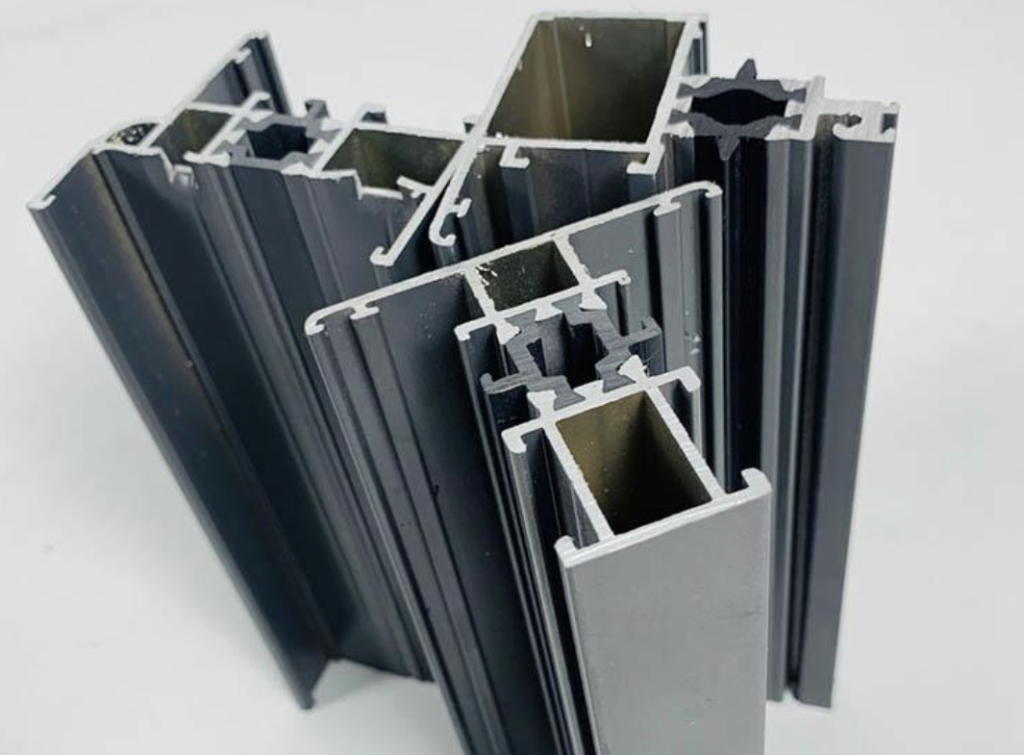

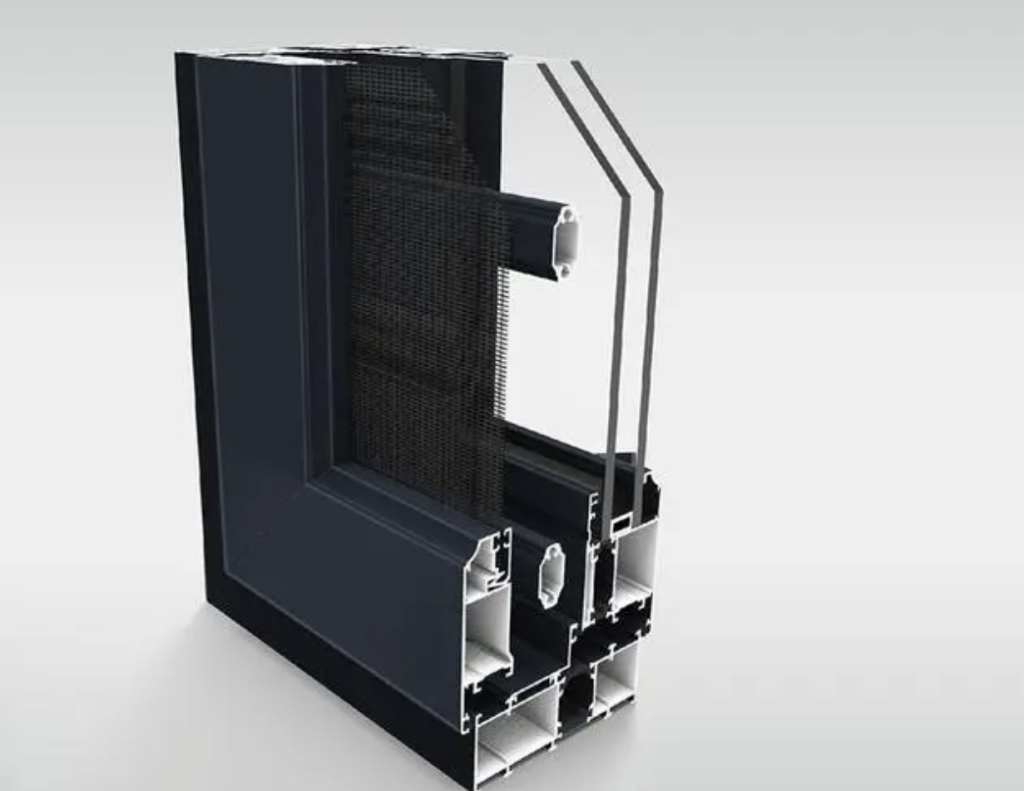

– Building doors and windows:

Because of its good workability and weldability, 6063 aluminum alloy is commonly used to manufacture the frames and fan blades of architectural doors and windows.

In the manufacture of windows and doors, the lightweight characteristics of aluminum profiles (density of about 2.7g/cm³) can reduce the overall weight of the building, while its corrosion resistance to ensure that the doors and windows of the long-lasting use.

– Curtain wall materials:

6061 aluminum alloy is commonly used to manufacture support structures and decorative strips for curtain walls due to its high strength and good workability.

And the curtain wall as the facade of the building, its use of extruded aluminum 6061 has the strength to support the structure. And also has good appearance and weather resistance.

Heat sink:

Aluminum profile 6061 can have the advantages of corrosion resistance and plasticity. This enables it to be the main material for heat sinks.

It can be extruded to produce heat sinks of various shapes. The manufacturing cost is much lower than copper heat sinks, so it can occupy the absolute market in the same type of heat sink.

Guardrail and fence material:

It can be the material for railings and various types of fences. Because 6063 aluminum profile can be powder coated and anodized and other surface treatment. This means it can fulfill all types of outdoor railing designs.

Common aluminum grades in 6xxx series:

Grade 6063 aluminum:

Aluminum grade 6063 is the most used extruded aluminum in the 6xxx aluminum series. It is transformed by aluminum extrusion into aluminum door and window frames, aluminum channels and building frames. It is the aluminum alloy that we come into contact with most in our lives.

Advantages of grade 6063 aluminum:

Excellent corrosion resistance:

6063 aluminum alloy has high resistance to oxidation corrosion. It can be used for long periods of time in humid, high temperature and corrosive environments. This makes it particularly suitable for use in areas such as marine construction and marina materials

Excellent plasticity

Aluminum 6063 is the softest of the 6xxx series of aluminum, which means that its malleability will be excellent. It can be extruded to obtain complex shapes to meet a wide range of demanding construction projects.

Cold Forming

Aluminum grade 6063 has moderate to good cold working properties. When supplied in T4 condition, bending and folding are never a problem. It is a good choice for use as bent aluminum tubing or bent aluminum parts.

Chemical composition of 6063 grade

| element | content% |

|---|---|

| aluminum(Al) | 95.85% – 98.56% |

| silicon(Si) | 0.20% – 0.66% |

| iron(Fe) | ≤ 0.35% |

| copper(Cu) | ≤ 0.10% |

| manganese(Mn) | ≤ 0.10% |

| magnesium(Mg) | 0.45% – 0.99% |

| chromium(Cr) | ≤ 0.10% |

| zinc(Zn) | ≤ 0.10% |

| titanium(Ti) | ≤ 0.10% |

Grade 6082 aluminum:

Grade 6082 is the hardest aluminum alloy in the 6000 series. Because it has the highest silicon metal content, this means that this grade can be used in more demanding weapons, military and aircraft parts.

Advantages of grade 6082 aluminum:

High Strength:

Aluminum alloy 6082 has high strength, which can be further increased when it is heat treated. It is suitable for projects where high loads are required but parts are lightweight. Examples include satellites, airplanes and automotive parts.

Machining:

6082-T6 is an aluminum alloy that is ideally suited for machining. It works well as a material in machining. Common cutting and drilling can be used in it, if you want a strong aluminum part 6082-T6 can satisfy you.

Chemical composition of 6082 grade:

| element | content % |

|---|---|

| aluminum(Al) | 98.3%-95.4% |

| silicon(Si) | 0.7% – 1.3% |

| magnesium(Mg) | 0.6% – 1.2% |

| manganese(Mn) | 0.4% – 1.0% |

| chromium(Cr) | ≤ 0.25% |

| copper(Cu) | ≤ 0.10% |

| zinc(Zn) | ≤ 0.20% |

| titanium(Ti) | ≤ 0.10% |

| iron(Fe) | ≤ 0.50% |

Grade 6061 aluminum:

Grade 6061 is a medium-strength aluminum alloy produced primarily for the U.S. market. 6082 is the closest grade to this grade, but 6082 is much more expensive. In fact, the difference between 6061 and 6082 is very small indeed. If you want a tough aluminum product, using 6061 is also a good option.

Physical properties of grade 6061 aluminum

- Density: about 2.75g/cm³

- Poisson’s ratio: 0.330

- Yield strength: above 110MPa

- Elongation: 16.0% or more

- Tensile strength: range from 150MPa to 290MPa

Heat treatable:

6061 aluminum alloy belongs to the heat treatment can be strengthened alloy, it through the solid solution treatment and aging treatment can significantly improve the strength and hardness of the material. Therefore, the hardness of 6061-T6 is close to that of grade 6082. The strength of 6061 can reach the hardest after strengthening by heat treatment.

Chemical composition of 6061 grade:

| element | content % |

|---|---|

| aluminum(Al) | 98.5%——99.2% |

| silicon(Si) | 0.40%——0.80% |

| copper(Cu) | 0.15%——0.40% |

| magnesium(Mg) | 0.80%——1.20% |

| Zinc(Zn) | 0.25% |

| manganese(Mn) | 0.15% |

| chromium(Cr) | 0.04%——0.35% |

| titanium(Ti) | 0.15% |

| Iron(Fe) | 0.70% |

In summary

With its excellent physical properties, processing performance and corrosion resistance, 6000 series aluminum alloy are widely used in the construction field.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including aluminum roofings,aluminum heat sink aluminum T-slot profile, aluminum deck, aluminum fence, aluminum doors and windows, solar aluminum frame. We offer huge quantity of aluminum building materials and factory price.