What is 6005 Aluminum

6005 belongs to the Al-Mg alloy, which is the most promising alloy for a wide range of applications, especially in the construction industry.

It has good corrosion resistance, excellent weldability, good cold workability and moderate strength.

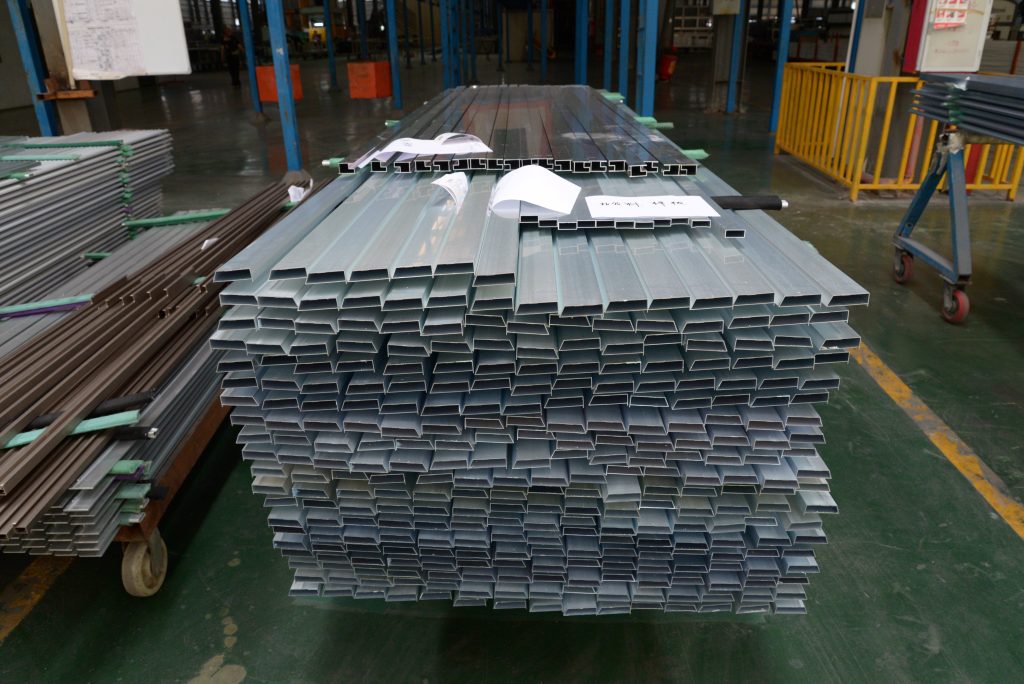

Aluminum 6005 can be easily processed and is generally obtained by aluminum extrusion. It plays a role as aluminum extrusion in the fields of construction, electronics, and aerospace.

6005 aluminum alloy applications:

Mechanical parts materials:

Because of its high strength and good corrosion resistance, 6005 aluminum alloy is often used to make various mechanical parts, such as brackets and containers. These parts need to withstand certain loads and harsh working environments, and 6005 aluminum alloy can well meet these requirements.

Material for car body and frame:

In automotive manufacturing, 6005 aluminum alloy is widely used to make body and frame components because of its high strength and light weight. It helps to reduce the vehicle’s overall mass and improve fuel economy and driving stability.

Engine part materials:

Meanwhile, 6005 aluminum alloy is also used to make engine parts, such as engine mounts. These parts need to withstand harsh environments such as high temperatures and pressures, and 6005 aluminum alloy’s resistance to high temperatures and corrosion makes it capable of performing these tasks.

Electronic equipment enclosures, heat sinks:

6005 aluminum alloy is also widely used in the electronic field due to its good thermal and electrical conductivity. It is often used to make electronic equipment shells and heat sinks and other components to improve the thermal performance and conductivity of the equipment.

It can be polished.

Uses are mainly used for the requirement of high plasticity and good weldability, working in liquid or gaseous media, low load parts, such as fuel tanks, gasoline or lubricating oil conduits. Sheet metal parts for transportation vehicles and ships. Instrumentation, street lamp brackets and rivets, hardware products, electrical enclosures, etc.

Mechanical properties

| aluminum alloy | tensile strength(Rm)/MPa | Yield Strength(Rp0.2)/MPa | Elongation after fracture(A)/% | Hardness (reference value) |

|---|---|---|---|---|

| 6005-T5 | 260 – 270 | 215 – 240 | 8 – 10 | HW:about 15-15.3 |

| 6005-T6 | 270 – 304 | 225 – 264 | 10 – 13 | (HB)≤180 |

Metal composition:

| Chemical Element | % Present |

|---|---|

| Manganese (Mn) | 0.0 – 0.50 |

| Iron (Fe) | 0.0 – 0.35 |

| Magnesium (Mg) | 0.40 – 0.70 |

| Silicon (Si) | 0.50 – 0.90 |

| Zinc (Zn) | 0.0 – 0.20 |

| Titanium (Ti) | 0.0 – 0.10 |

| Chromium (Cr) | 0.0 – 0.30 |

| Copper (Cu) | 0.0 – 0.30 |

| Manganese + Chromium (Mn+Cr) | 0.12 – 0.50 |

| Other (Each) | 0.0 – 0.05 |

| Others (Total) | 0.0 – 0.15 |

| Aluminium (Al) | 98.9 and above |

Please note that the content ranges in this table are based on a general case 6005 aluminum alloy composition. However, actual production 6005 aluminum alloy compositions may be adjusted based on specific application requirements and manufacturer’s specifications.

6005 aluminum alloy leading our industry!

Aluminum 6005 is a widely used rust-proof aluminum alloy. It is characterized by corrosion resistance, fatigue strength, good weldability and plasticity. It can be used in transportation conduits, vehicles, ships and electronic heat dissipation parts. Based on its advantages, it can become the material for more parts in the future ship and transportation industry.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including 5000 series aluminum profile,6000 series aluminum profile, 7000 series aluminum profile. We offer High quantity of extruded aluminum product and factory price.