What is 6005-T5 Aluminum Extrusion?

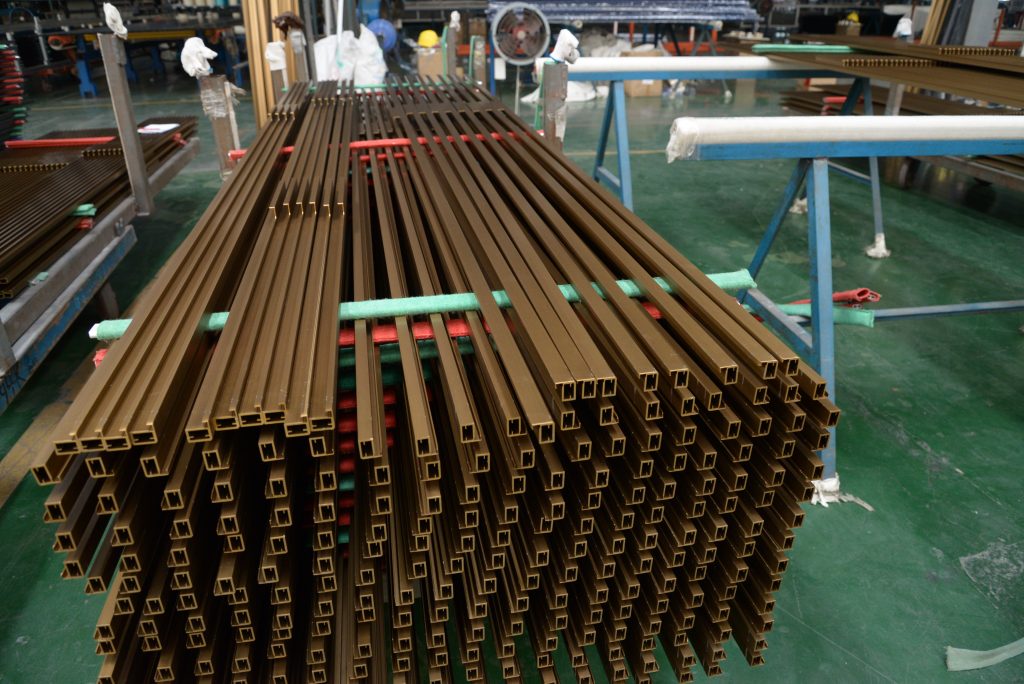

6005-T5 Aluminum Extrusion is a durable and versatile alloy widely used in construction and industrial applications. It combines strength, corrosion resistance, and ease of fabrication, making it ideal for projects that require lightweight yet strong materials.

This alloy is commonly employed in structural frameworks, transportation systems, and other engineering designs where reliability and performance are key.

Below, we explore the essential characteristics, composition, and applications of 6005-T5 Aluminum Extrusion to help you understand why it is a preferred choice for manufacturers and engineers.

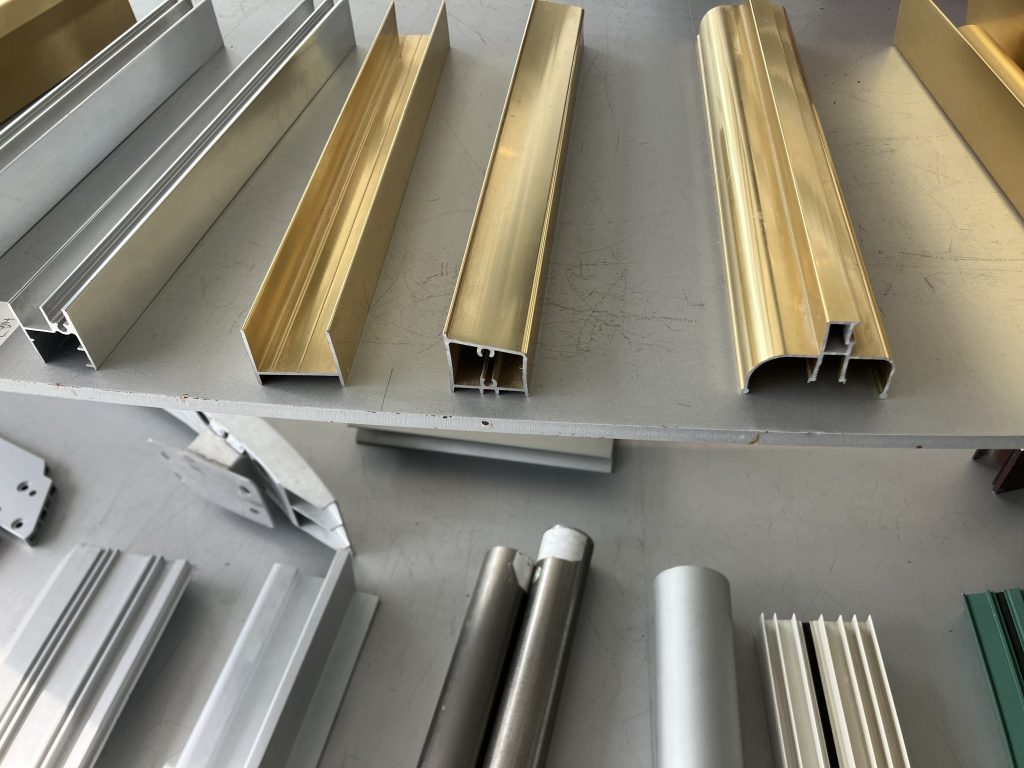

Related products: Extruded aluminum profiles

6005-T5 Aluminum Extrusion: Composition, Heat Treatment, and Key Properties

Material Composition

6005-T5 aluminum extrusion is an alloy primarily composed of aluminum, magnesium, and silicon, with magnesium and silicon acting as the primary strengthening agents. These elements improve the alloy’s durability, corrosion resistance, and structural integrity.

In addition to these main components, small amounts of copper, zinc, manganese, chromium, and lead are included. These trace elements enhance specific properties, such as machinability and wear resistance. For example:

- Copper contributes to better electrical conductivity.

- Manganese improves resistance to wear and deformation.

- Chromium enhances corrosion resistance in certain environments.

Heat Treatment State

The “T5” designation refers to a specific heat treatment process that shapes the mechanical properties of the 6005 aluminum alloy. This process involves:

- Solid Solution Treatment: Heating the alloy to dissolve alloying elements uniformly into the aluminum matrix.

- Artificial Aging (Incomplete): Cooling the material and allowing partial precipitation of strengthening phases to balance hardness and ductility.

This controlled aging process ensures the alloy achieves sufficient strength while retaining flexibility, making it suitable for applications requiring both durability and adaptability, such as structural frameworks or transportation components.

Key Benefits of 6005-T5 Aluminum Extrusion

- High strength-to-weight ratio for lightweight yet durable designs.

- Excellent corrosion resistance for outdoor or marine environments.

- Good machinability for complex shapes and custom profiles.

Combining carefully selected materials with precise heat treatment, 6005-T5 aluminum extrusion delivers reliable performance across diverse industries.

Key Physical Properties

6005-T5 aluminum extrusion is recognized for its lightweight and durable characteristics, making it ideal for structural applications. Below are its key physical properties:

Density

2.7 g/cm³ (or 2700 kg/m³): This low density makes 6005-T5 aluminum an excellent choice for applications requiring lightweight components without sacrificing strength.

Engineers often use this material in industries like transportation and construction, where reducing weight improves efficiency and performance.

Melting Point

607–654°C: The melting point range ensures the alloy can withstand moderate thermal conditions.

This property makes it suitable for outdoor structures and heat-dissipating components, such as radiators and heat exchangers.

Why Do These Properties Matter?

The combination of low density and moderate heat resistance positions 6005-T5 aluminum as a versatile material. It balances strength and adaptability, offering a practical solution for projects where weight reduction is critical but durability cannot be compromised. For example:

- Transportation: Lightweight profiles reduce fuel consumption in vehicles.

- Construction: Durable yet easy-to-install frameworks simplify building processes.

Key Takeaways

6005-T5 aluminum extrusion delivers measurable advantages:

- Lightweight design for improved efficiency.

- Reliable performance in environments with temperature fluctuations.

These properties make it a preferred material across industries seeking cost-effective, high-performing solutions.

Mechanical Properties

6005-T5 aluminum extrusion is known for its balanced mechanical properties, making it a popular choice for applications requiring strength, durability, and workability. Below is a concise overview of its key mechanical attributes:

Tensile Strength (Rm: ~280 MPa)

This alloy offers a tensile strength of approximately 280 MPa, meaning it can withstand high forces without breaking. Its strong load-bearing capacity makes it ideal for structural components and heavy-duty applications.

Yield Strength (Rp0.2: ~235 MPa)

The yield strength is about 235 MPa, indicating the stress level at which the material begins to deform permanently. This ensures the alloy can handle significant stress while maintaining its structural integrity, making it reliable for demanding environments like construction and transportation.

Ultimate Elongation (A5: ~8%)

With an elongation of around 8%, this material offers moderate ductility. It can stretch or bend to a limited extent without cracking, which is essential for processes like bending, forming, or machining. This balance between flexibility and strength enhances its versatility for various manufacturing needs.

Brinell Hardness (HB80)

The Brinell hardness rating of 80 signifies moderate hardness. This allows the alloy to resist wear while remaining easy to machine and shape. It is particularly well-suited for applications requiring precision fabrication or intricate profiles.

Why Do These Properties Matter?

The combination of high tensile strength, reliable yield strength, moderate ductility, and manageable hardness makes 6005-T5 aluminum extrusion a practical choice for industries such as construction, automotive, and aerospace.

By understanding these properties, you can make informed decisions about using 6005-T5 aluminum in your projects—ensuring both efficiency and reliability in your designs.

Key Characteristics of 6005-T5

High Strength

6005-T5 aluminum extrusion offers robust strength, making it ideal for structural components across engineering applications. Its durability supports heavy loads and complex designs, ensuring reliability in demanding environments like construction and transportation.

Excellent Corrosion Resistance

The alloy’s composition, featuring magnesium and silicon, provides strong resistance to corrosion. This makes it suitable for outdoor installations, marine applications, and other settings where exposure to moisture or chemicals is common.

Reliable Welding Performance

6005-T5 aluminum is highly weldable using methods such as MIG, TIG, and resistance welding. Its compatibility with various techniques allows for smooth assembly while maintaining structural integrity in finished products.

Efficient Cold Workability

This material performs well in cold processing techniques like stamping, bending, and stretching. Its flexibility enables precise shaping for applications like automotive parts, architectural profiles, and industrial components without compromising strength.

Key Advantages at a Glance:

- Strength: Durable enough for heavy-duty applications.

- Corrosion Resistance: It withstands harsh environments effectively.

- Weldability: Supports multiple welding methods for seamless integration.

- Cold Workability: Easily shaped into custom designs with precision.

6005-T5 aluminum extrusion combines these characteristics to meet the needs of industries requiring high-performance materials with versatile processing capabilities.

Key Applications Across Industries

With its strength, durability, and versatility, 6005-T5 aluminum extrusion drives innovation in aerospace, automotive, and electronics. Its unique properties meet the needs of modern engineering.

Aerospace Industry

6005-T5 aluminum is widely used in aerospace because of its strength and low weight. It is a key material for aircraft frames, support beams, and wing structures. The alloy reduces overall weight while keeping structures strong. Its natural corrosion resistance ensures durability in high-altitude conditions.

Automotive Manufacturing

Automakers use 6005-T5 aluminum for chassis frames, crash management systems, and suspension parts. Its high thermal conductivity makes it ideal for engine components and heat exchangers. By using this alloy, manufacturers build lighter vehicles that improve fuel efficiency while maintaining safety and performance.

Electronics and Consumer Devices

6005-T5 aluminum is popular in electronics for enclosures, heat sinks, and brackets in devices like laptops, smartphones, and LED lights. It allows for precise machining, supports complex designs, and helps dissipate heat efficiently. These properties make it a top choice for durable and high-performance consumer electronics.

Final Thoughts

6005-T5 aluminum is more than just a material—it’s a solution for industries looking to innovate without compromising efficiency or cost-effectiveness. By choosing this alloy, manufacturers can achieve both performance and reliability, ensuring their projects succeed in competitive markets.

If you’re considering materials for your next project, 6005-T5 aluminum extrusion could be the key to achieving your goals with precision and practicality.