What is 6060 aluminum extrusion

Dimensions and specifications of 6060 aluminum:

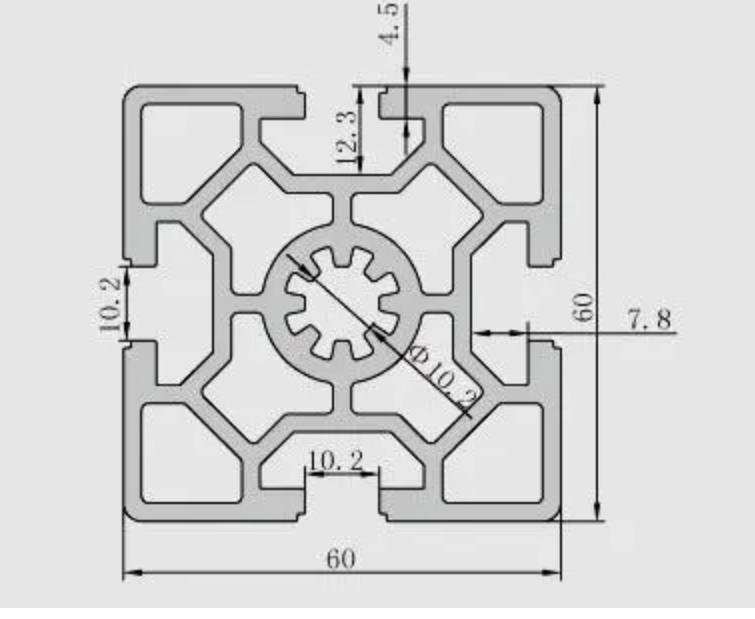

The cross sectional size of 6060 aluminum profiles is 60 x 60mm.

It is available in two main sizes of slot width: 8mm and 10mm. wherein, profiles with a slot width of 8mm are double-slot profiles (models such as 001.08.60.60), while profiles with a slot width of 10mm are single-slot profiles (models 001.010.60.60L, 001.010.60.60W).

– Within these specifications, there are standard, light and heavy profiles to meet different application requirements.

1. Its connecting fittings:

6060 aluminum profile fittings are generally connected using external corner pieces 6060 T-bolts, 3030M8 and flange nuts M8.

Profiles with a slot width of 8mm are fixed with cylindrical head bolts M8, while profiles with a slot width of 10mm are fixed with cylindrical head M12 and cross-fixed with special bolts M8 or M12.

Advantages of 6060 aluminum extrusion:

1. High strength and durability:

Aluminum 6060 has high strength properties and good corrosion resistance, able to withstand large loads and pressures without deformation or fracture. This gives it a significant advantage in areas that require high stress and high strength support. 2.

2. Excellent processability and molding performance:

The profile has good processing performance and can be processed into various shapes to form a good modeling effect. At the same time, its molding performance is also better, to meet the needs of different application scenarios.

3. Wide range of applications:

6060 aluminum extrusion is widely used in a variety of fields that require large stress and high strength support.

Such as heavy-duty measuring equipment racks, large workshop intelligent transformation production lines, large robot safety guards, heavy aluminum profile equipment frames and so on. In addition, it has a wide range of applications in construction, decoration, transportation and machinery manufacturing.

4. Easy to install and maintain:

As the connecting fittings of 6060 aluminum extrusion are well-designed, it makes its installation process simple and fast. Meanwhile, the maintenance cost is relatively low due to its good corrosion resistance.

This video shows aluminum extrusion processing:

Disadvantages of 6060 aluminum extrusion:

1. Price factor: 6060 aluminum may be more expensive compared to some traditional materials. This may limit its application in some cost-sensitive areas.

2. Poor high-temperature performance: Compared with some high-temperature alloys, the high-temperature performance of 6060 aluminum may be slightly inferior. Therefore, special attention needs to be paid to its performance when used in high temperature environments.

Application areas:

6060 aluminum due to its high strength, high stability, corrosion resistance and easy to install and other characteristics.

It is widely used in a variety of areas that require high stress and high strength support. Such as heavy-duty measuring equipment racks, large-scale intelligent transformation of the workshop production line, large-scale robot safety guards, heavy-duty aluminum equipment frames and so on.

Summary:

6060 aluminum is a kind of aluminum profile with various specifications, high strength, high stability, corrosion resistance and easy to install and other characteristics, widely used in a variety of fields that require high strength support.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, CNC and product design processing capabilities. We are 15 years experienced aluminum extrusion supplier and can offer you factory price and high quality products.