What is 6061-T6 Aluminum Flat Bar?

6061-T6 aluminum bars are strong and versatile and used in many industries. They have a great strength-to-weight ratio and high corrosion resistance, making them ideal for construction, automotive, and manufacturing applications. The term “6061” refers to the specific aluminum alloy, while “T6” indicates the heat treatment that improves its mechanical properties.

This article will cover the characteristics, benefits, manufacturing process, and applications of 6061-T6 aluminum bars. Whether you are a professional or a DIYer, you will learn something here to help you make informed decisions for your projects.

Related products: Aluminum Bars Stock

Main Alloying Elements and Properties

6061-T6 aluminum contains two main alloying elements: magnesium (Mg) and silicon (Si). These elements combine to form Mg2Si, which increases the strength and hardness of the aluminum flat bar.

The magnesium content ranges from 0.8% to 1.2%. The silicon content is between 0.4% and 0.8%. This combination enhances the overall performance of 6061-T6 aluminum, making it suitable for various applications that require durability and corrosion resistance.

The presence of magnesium and silicon in 6061-T6 aluminum significantly improves its strength and hardness, making it a preferred choice for demanding environments.

Physical and Chemical Properties

Strength

6061-T6 aluminum alloy is strong. Its tensile strength reaches about 276 MPa, making it suitable for demanding applications.

Corrosion Resistance

This alloy resists corrosion effectively. It performs well in various environments, which helps prolong its lifespan.

Weldability

6061-T6 aluminum has excellent weldability. You can join it using different welding methods, adding to its versatility.

Machinability

The machinability of 6061-T6 aluminum is impressive. It can be easily machined with standard methods like milling, drilling, and stamping.

6061-T6 aluminum flat bars offer strength, corrosion resistance, weldability, and machinability. These properties make them a preferred choice in many industries.

Manufacturing Process

The manufacturing process of 6061-T6 aluminum flat bars includes extrusion, stretching, and surface treatment. Each step is essential for producing high-quality aluminum products suitable for various applications.

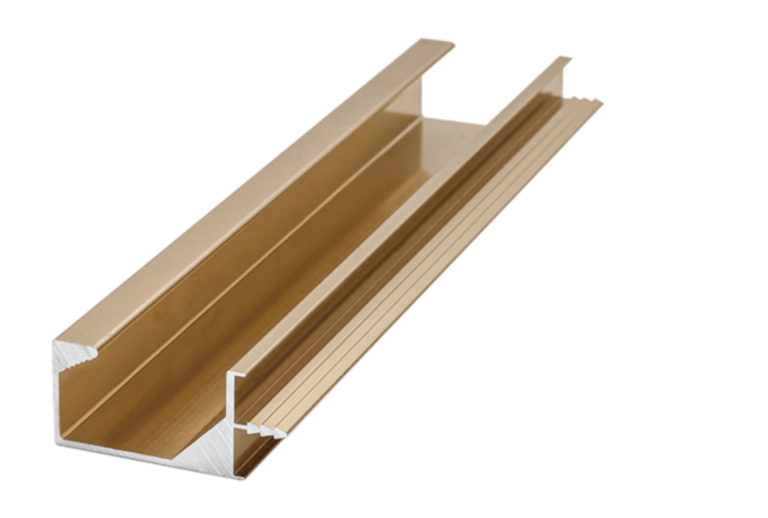

Aluminum Extrusion

The manufacturing process for 6061-T6 aluminum flat bars starts with aluminum extrusion. Manufacturers create a mold based on the desired cross-section. They heat a round aluminum cast bar and use an extruder to push it through the mold. Operators control temperature, pressure, and speed during this process to maintain product quality.

Stretching the Aluminum Flat Bar

After extrusion, the aluminum bars undergo stretching. They are placed in a stretching machine where tensile force is applied. This process deforms the bars at a specific temperature. As a result, the bars become thinner and their mechanical properties improve.

Surface Treatment

Once shaped, the aluminum flat bars receive surface treatment. Common methods include powder coating and anodizing. These treatments protect the surface from corrosion and damage from strong acids.

Practical Applications

6061-T6 aluminum flat bars have many industrial uses. They are ideal for structural parts that require strength and high corrosion resistance. Common applications include:

- Railway Vehicles: These bars provide durability for train components.

- Furniture: They are used in furniture frames and supports, offering strength with a lightweight design.

- Machinery Parts: Many machinery components rely on 6061-T6 aluminum for its strength and wear resistance.

- Precision Machining: This alloy is suitable for precision parts that need accuracy and reliability.

- Molds: It is often used in mold-making due to its excellent machinability and strength.

6061-T6 flat bars extrusions are versatile and essential across various industries. Their combination of strength and corrosion resistance makes them a preferred choice for demanding applications.

Final Thoughts

6061-T6 extruded flat bars are strong and corrosion-resistant materials used in construction and industrial applications. They are made through an aluminum extrusion process, which shapes the material into the desired profile.

Hugh Aluminum is a manufacturer based in China that specializes in aluminum extrusion. We produce a variety of aluminum flat bars to meet different needs. With 14 years of experience, we have served nearly forty countries and over six hundred customers.