What is 7000 Series Aluminum?

7000 series aluminum is a high-strength alloy that combines aluminum, zinc, copper, and magnesium. It is one of the hardest aluminum alloys, with tensile strengths reaching up to 680 MPa after heat treatment. Its strength-to-weight ratio is comparable to super-strength steel, making it ideal for demanding applications.

This alloy is lightweight, durable, and resistant to extreme conditions. Industries rely on it for aerospace components, automotive parts, and structural elements in high-performance machinery. Its combination of strength and low weight makes it a top choice for engineers designing critical structures.

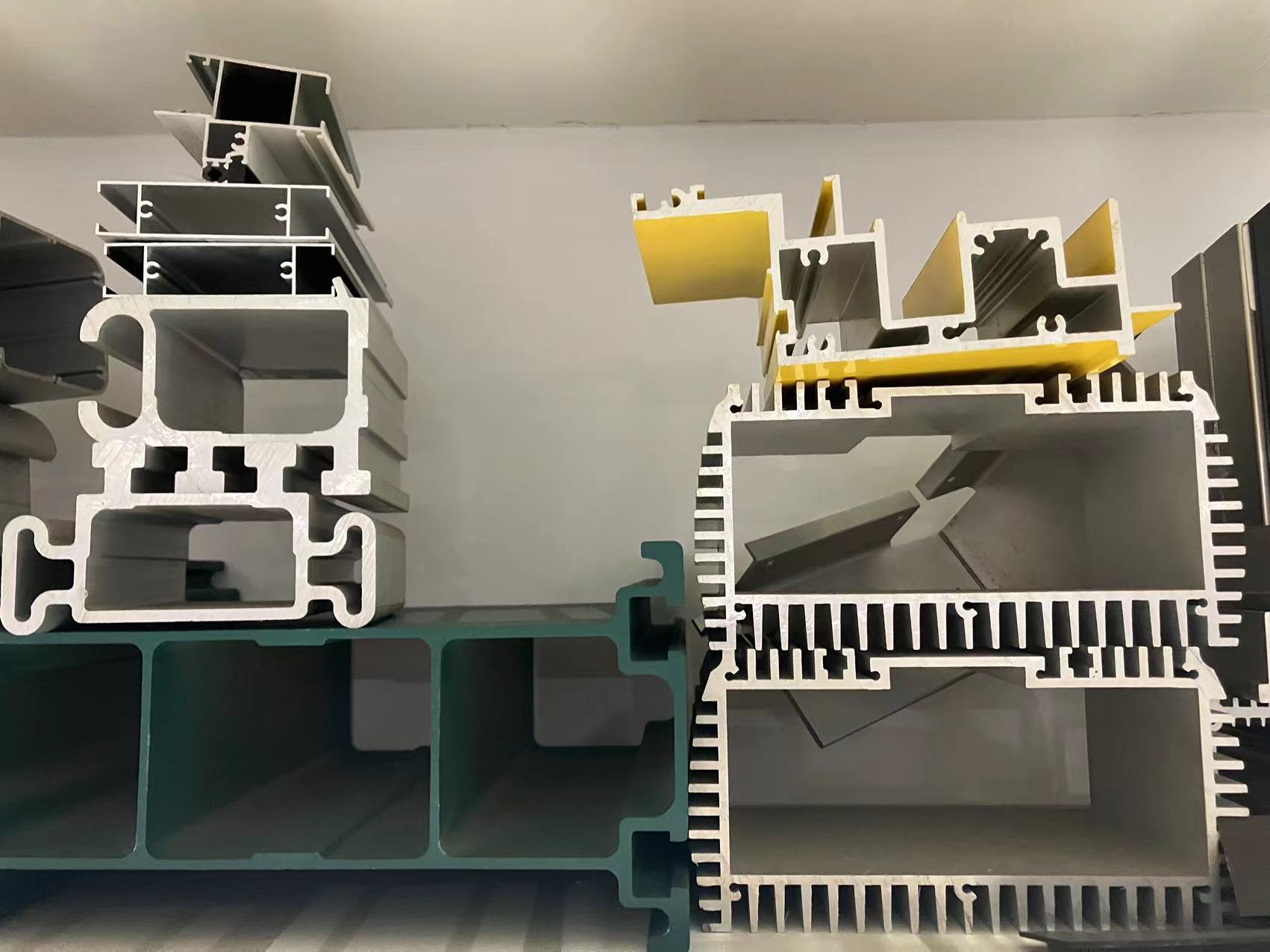

Related products: Extruded aluminum profiles

Key Characteristics of 7000 Series Aluminum

- High Strength – Reaches tensile strengths up to 680 MPa, offering a strength-to-weight ratio similar to steel.

- Corrosion Resistance – It withstands environmental exposure, especially with protective coatings.

- Lightweight – Maintains low density while providing strong structural support.

- Heat Treatment Compatibility – Strength and durability improve significantly after solid solution treatment and aging.

Why Industries Use 7000 Series Aluminum?

This alloy performs well under extreme conditions, making it a top choice for:

- Aerospace – Used in aircraft frames and components that endure high stress.

- Automotive – Provides strength for lightweight performance vehicle parts.

- Sports Equipment – Reinforces bicycle frames and other gear without adding weight.

- Defense – Strengthening military vehicle structures and equipment.

Its durability and low weight make it essential for applications where material failure is unacceptable.

Advantages Over Other Aluminum Alloys

The 7000 series is stronger than most aluminum alloys at room temperature. While other alloys focus on flexibility or corrosion resistance, this series prioritizes load-bearing capacity, making it ideal for high-stress applications.

Learn more: What is the 6000 series aluminum extrusion?

Types of 7000 Series Aluminum

The 7000 series aluminum alloys are strong, durable, and corrosion-resistant. These properties make them essential in aerospace, transportation, and sports equipment manufacturing. Below is a breakdown of the key types:

7005 Aluminum

Manufacturers commonly use 7005 aluminum in extrusion applications for its strength and fracture toughness. It is ideal for:

- Transportation – Trusses, rods, and containers

- Industrial Equipment – Large heat exchangers

- Sports Gear – Tennis rackets and baseball bats

This alloy works well for welded structures that cannot undergo a solid solution treatment after welding.

7049 Aluminum

7049 aluminum is designed for forged parts that need high strength and resistance to stress corrosion. It is used for:

- Aerospace – Landing gear hydraulic cylinders

- Defense – Missile components

It has similar fatigue properties to 7075-T6 aluminum but offers better toughness.

7050 Aluminum

7050 aluminum is optimized for aerospace structures. It performs well in:

- Aircraft Construction – Wing spars and fuselage frames

- Structural Components – Medium and thick plates, extrusions, and forgings

This alloy resists corrosion, stress cracking, and fatigue, making it reliable for high-stress applications.

7039 Aluminum

7039 aluminum maintains stability across a wide temperature range, making it useful for:

- Refrigeration – Storage tanks and cooling containers

- Emergency Equipment – Fire-fighting pressure devices

- Defense – Military armor plates and missile components

Its ability to withstand extreme conditions makes it valuable in the industrial and military sectors.

7475 Aluminum

7475 aluminum offers high strength and fracture toughness, making it a preferred choice in aviation. It is commonly used for:

- Aerospace – Aircraft wing structures and trusses

- Structural Applications – Clad and unclad plates

Its durability allows it to handle the stresses of flight and high-performance engineering.

Each alloy in the 7000 series serves a specific purpose, offering strength and durability for industries that demand high-performance materials.

Conclusion

The 7000 series aluminum is one of the strongest and most durable aluminum alloys. Its high tensile strength and hardness make it essential in aerospace, aviation, and defense. These properties allow it to perform reliably under extreme conditions.

The demand for lightweight, high-strength materials continues to grow. The 7000 series aluminum is expected to play a role in new technologies, including space exploration. Its durability and low weight make it a strong candidate for spacecraft and other advanced engineering projects.

As industries push the limits of innovation, this alloy will remain a key material for building stronger, lighter, and more efficient structures.