What is 7075 Aluminum

What is 7075 Aluminum?

Aluminum 7075 is a cold worked forging alloy. It is an ultra-high strength aluminum alloy material. The main component of this alloy is zinc, with small amounts of magnesium and copper elements.

It has excellent mechanical properties and anodic reaction characteristics, and excels especially in applications requiring high stress and corrosion resistance.

Its main metal composition:

- Aluminum (Al): as a matrix element, the content of aluminum accounts for the absolute majority in 7075 aluminum alloy, usually accounting for more than 90%.

- Zinc (Zn): It is one of the main alloying elements in 7075 aluminum extrusion, and its addition can increase the strength and hardness of the aluminum alloy and improve the wear resistance. The range of zinc content is roughly between 5.1% and 6.8%.

- Magnesium (Mg): also an important alloying element of 7075 aluminum extrusion, its addition can improve the plasticity and toughness of aluminum alloy and make it have better cutting and machining performance. The content of magnesium ranges from 2.1% to 2.9%.

- Copper (Cu): the addition of copper can enhance the strength and corrosion resistance of aluminum alloy. In 7075 aluminum alloy, the content of copper ranges roughly from 1.2% to 2.0%.

Other elements: - Chromium (Cr): in 7075 aluminum profiles, the content of chromium is usually low, but can play a certain role in strengthening. Its content range is roughly between 0.18% and 0.28%.

What is its processing?

Aluminum Extrusion:

It refers to the aluminum 7075 billet placed in the die cavity to apply strong pressure, forcing the aluminum billet to produce directional plastic deformation, extrusion from the die hole of the extrusion die, so as to obtain the desired cross-section shape of the aluminum products.

Heat Treatment:

Aluminum 7075 extrusion is usually subjected to heat treatment processes, such as solid solution treatment and aging, to improve its strength and hardness. These heat treatment processes remove internal stresses and improve material properties.

Surface Treatment:

Surface treatments are applied to 7075 aluminum extrusion according to the needs of the application. Such as anodizing, spraying and polishing.

These surface treatments can improve its corrosion resistance and aesthetics

Belows video from Hugh Aluminum shows extrusion processing:

The following are its main advantages:

High Strength:

It has extremely high tensile and yield strengths that far exceed those of many other aluminum alloys and common steels. This allows it to excel in applications that require it to withstand high stresses and loads.

Lightweight:

Despite its high strength, 7075 aluminum. However, its relatively low density makes it lightweight. This lightweight, high-strength characteristic makes it particularly popular in aerospace, automotive, and sports equipment applications, where it can reduce overall weight without sacrificing structural strength.

Good corrosion resistance:

It has good corrosion resistance and is resistant to a wide range of chemicals. This makes it excellent in marine environments, chemical equipment, and other applications that need to withstand corrosive media.

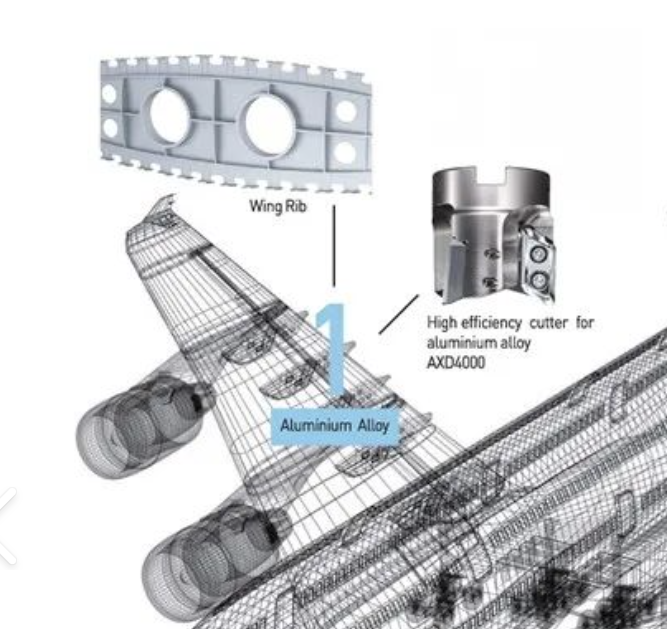

Excellent machinability:

Aluminum 7075 has excellent machinability. It can be molded and machined through a variety of processes such as hot extrusion, forging, and machining. In addition, it can be subjected to joining processes such as welding and riveting, facilitating the manufacture of complex structures and components.

Excellent toughness:

It is not only strong, but also has good toughness. This means it can maintain structural integrity and stability when subjected to shock and vibration, improving product safety and reliability.

In conclusion

It should be noted that 7075 aluminum profiles are relatively expensive due to their alloy composition and manufacturing process, so you need to weigh the relationship between their performance and cost when using them.

Hugh Aluminum is an aluminum extrusion manufacturer located in China. Currently has 25,000 square meters of production space and 250+ employees.

We produce aluminum extrusion products containing 5000-7000 series alloys. For example 7075 aluminum extrusion.

If you want to purchase it in bulk or know about these products please contact us.