What is a LED Light Heat Sink? Complete Guide to LED Cooling & Performance

LED lights save energy and last longer than traditional bulbs, but they generate heat that can shorten their lifespan. An LED heat sink removes this heat and keeps the light working at peak performance.

This guide explains how LED heat sinks work, why they matter, and how to choose the best one for your needs. Read on to protect your LEDs and get the most from your lighting.

Introduction to LED Light Heat Sinks

LED lights generate heat as they operate. This heat can damage the LED chip if not removed quickly. An LED heat sink absorbs and disperses this heat, keeping the light cool and functioning well.

Heat sinks work like radiators in a car. They draw heat away from the LED and release it into the air. Without a heat sink, the LED’s brightness drops, colors shift, and the light may fail early.

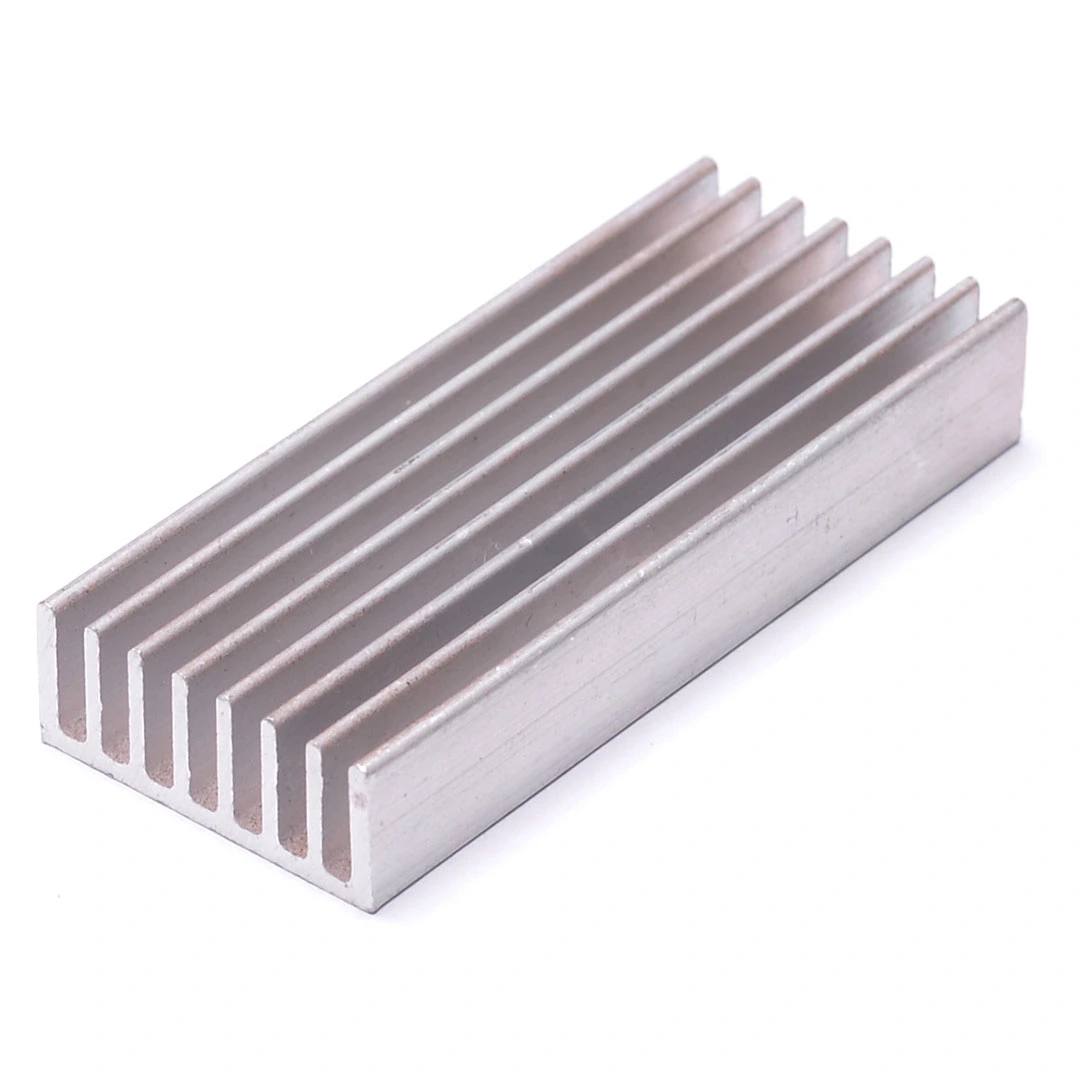

Most LED heat sinks use aluminum (aluminum heat sink) because it conducts heat efficiently and is lightweight. You’ll find these heat sinks in everything from household bulbs to industrial fixtures.

Effective heat sinking extends LED lifespan and maintains consistent light quality. If you want reliable, long-lasting LED lighting, choosing the right heat sink is essential.

Next time your LED shines brightly, remember the heat sink quietly prevents overheating and keeps your light performing at its best.

Why Do LEDs Need Heat Sinks?

LEDs convert electricity into light and heat at the semiconductor junction. This heat accumulates at the LED’s base if not removed quickly.

Excess heat causes several problems:

- Shortens lifespan: High temperatures accelerate material wear. For example, an LED rated for 50,000 hours may last only 20,000 hours if it overheats.

- Reduces brightness: Heat lowers luminous efficiency, causing LEDs to dim over time.

- Changes color: Overheating shifts LED color, making whites look yellow or blue.

- Creates safety risks: Heat buildup in enclosed spaces can lead to electrical failures or fire hazards.

High-power LEDs, like those in car headlights or spotlights, produce more heat. Without effective heat sinks, their temperature rises rapidly, causing performance loss or failure.

Heat sinks pull heat away from LED chips and spread it into the air. This cooling keeps LEDs bright, stable, and long-lasting.

Choosing the right heat sink is essential for reliable LED performance and safety.

How Does an LED Heat Sink Work?

An LED heat sink removes heat from the LED chip and releases it into the air. This process protects the LED from overheating.

The process includes:

- Heat Generation: The LED chip creates both light and heat during operation. For example, a 10-watt LED may convert 8 watts into heat.

- Heat Transfer: Heat moves from the chip to the heat sink through a metal core PCB. Good contact speeds up this transfer.

- Heat Dissipation: The heat sink, often made of aluminum with fins, spreads heat over a large surface. Airflow carries the heat away.

- Temperature Control: The LED stays within a safe temperature range. This prevents damage and keeps light output stable.

A working LED bulb feels warm at the back. This warmth shows the heat sink is moving heat away from the LED chip, keeping the light reliable and long-lasting.

Types of LED Heat Sinks

LED heat sinks use different materials and designs to manage temperature and maintain performance.

Common Heat Sink Materials

| Material | Key Features | Typical Applications |

|---|---|---|

| Aluminum | Lightweight, affordable, good heat transfer | Most general LED fixtures |

| Copper | Superior heat transfer, heavier, costly | High-power and industrial LEDs |

| Polymer | Lightweight, moldable, moderate cooling | Specialized or compact LED designs |

By Heat Sink Designs

- Finned Heat Sinks: Thin fins increase surface area and help air move heat away. Common in streetlights and floodlights.

- Pin or Plate Heat Sinks: Pins or flat plates direct airflow in tight spaces. Useful for LED strips and compact fixtures.

- Custom and Bio-Inspired Shapes: Some heat sinks mimic natural forms, like tree branches, to improve cooling. Used in advanced or high-output LEDs.

By Manufacturing Methods

- Extruded Aluminum: Efficient, cost-effective shapes for most LED lights.

- Die-Cast Aluminum: Complex designs for high-volume production.

- Cold-Forged Aluminum: Strong, high-performance heat sinks for demanding uses.

- Machined Copper: Custom, high-heat applications.

Practical Examples

- A streetlight uses a large, finned aluminum heat sink for outdoor cooling.

- An LED strip uses a flat plate or polymer heat sink for a slim profile.

- An industrial spotlight relies on a copper heat sink to handle intense heat.

Selecting the right LED heat sink material and design keeps your lights cool, bright, and reliable.

Key Factors in LED Heat Sink Design

Several features determine how well an LED heat sink controls temperature and protects the light source.

Surface Area

A larger surface area lets more heat escape. Fins or extended surfaces help the heat sink release heat faster. For example, a finned heat sink cools better than a flat plate.

Fin Design

Fin spacing, thickness, and direction affect cooling. Wide gaps allow air to move freely. Thin fins add surface area without adding much weight. Vertical fins work well in ceiling-mounted lights.

Material Choice

Aluminum and copper transfer heat quickly. Aluminum is common for most LED fixtures. Copper works best in high-power or industrial lights.

Thermal Interface Materials

Thermal pads or paste fill the gaps between the LED and the heat sink. This layer improves heat transfer and prevents air pockets that trap heat.

Mounting and Integration

The heat sink must touch the LED module firmly. Loose mounting creates hot spots and reduces cooling.

Manufacturing Method

- Die-cast aluminum: Makes complex shapes but may trap air.

- Extruded aluminum: Produces consistent, high-quality fins.

- Cold-forged aluminum: Creates strong, dense heat sinks.

Example:

A warehouse light may use a large, extruded aluminum heat sink with thermal paste for top cooling. A compact spotlight may use a die-cast design for tight spaces.

Choosing the right features helps your LED lights stay cool and last longer.

How to Choose the Right Heat Sink for Your LED Application?

Calculate Power Dissipation

Find out how much heat your LED produces. For example, a 10-watt LED often generates about 8 watts of heat.

Set Maximum Junction Temperature

Check the LED datasheet for the highest safe operating temperature. Keep the LED’s junction temperature below this value to prevent damage.

Estimate Required Thermal Resistance

Use this formula:

Thermal Resistance (°C/W) = (Max Junction Temp – Ambient Temp) ÷ Power Dissipation.

Lower thermal resistance means better heat removal.

Consider Ambient Conditions

Account for room temperature, airflow, and enclosure design. Hot or enclosed spaces need larger or more efficient heat sinks.

Evaluate Size and Weight

Choose a heat sink that fits your fixture and does not add unnecessary weight. Oversized heat sinks can make installation difficult.

Check Material and Build Quality

Select aluminum or copper for high thermal conductivity. Look for precise engineering and solid construction.

Practical Example:

A recessed LED downlight in a 50°C room needs a large, efficient heat sink to keep the LED cool.

Quick Tips:

Apply thermal pads or paste to improve contact between the LED and heat sink. Match the fin design to your airflow for better cooling. Use passive cooling for most LEDs. Only use fans if passive methods are not enough.

The right heat sink keeps your LEDs bright and extends their lifespan.

Frequently Asked Questions (FAQ)

It can overheat, leading to rapid performance loss, color shifts, and early failure.

Yes, provided there is space and the design allows for secure attachment and proper thermal contact.

Regularly remove dust and debris to maintain optimal thermal conductivity and airflow.

Not necessarily—effectiveness depends on material, surface area, and design, not just weight.

Conclusion

LED heat sinks are essential for ensuring the performance, safety, and longevity of LED lighting. By understanding their function, types, and design considerations, you can select the right heat sink for any application, maximizing the benefits of your LED investment.