What is Aluminium Extrusion Plant

Extruded aluminium products have a vital role to play in modern society in construction, aerospace and transport. So how is it made? Let’s take an in-depth look at what an aluminium extrusion plant is today.

1.Production process of aluminium extrusion:

1. put the aluminium ingot into the heating furnace of the extruder and heat it to a certain temperature to soften the ingot sufficiently.

2. When the ingot is heated, it is placed into the die of the extruder. The die of the extruder usually consists of two semi-circular dies which can be closed tightly.

3. The two dies of the extruder, under the action of a hydraulic system, exert great pressure on the ingot, causing it to flow gradually towards the outlet of the die. During this process, the temperature and pressure of the ingot are constantly increasing.

4. When the ingot flows out of the outlet of the die, it has become the desired aluminium profile. At this point, the temperature of the aluminium profile is still high and needs to be cooled.

Here are the processing video of the aluminum extrusion from Hugh Aluminum

2. Type and size of plant

Generally aluminium extrusion plants are classified as small, medium and large. Because of their size, they have different production ranges and processing capabilities.

Small-sized aluminium extrusion plants generally only have the capability of die making, aluminium extrusion, cutting and hardening. They do not have the ability to process surface treatments.

Medium-sized aluminium extrusion plants include the processing of aluminium surface treatment, which usually includes powder coating, anodising and electrophoresis. In addition, the aluminium extrusion capacity is capable of producing larger sizes of profiles, typically in 2000 tonne extrusion lines.

A large aluminium extrusion plant will have all production functions. This includes forging, CNC, electrolytic aluminium and high precision aluminium extrusion manufacturing. It will often have fully automated lines and robots to manage production.

3.Aluminum Extrusion Plant Functions:

1. Die design and manufacture:

The factory will design and manufacture a die according to the shape and size of the aluminium profile to be extruded. The die usually consists of two semi-circular dies that can be closed tightly. The design of the extrusion die is important as poor design can result in grooves on the surface of the aluminium extrusion.

It should be noted that small aluminium extrusion plants are generally not capable of designing dies. Therefore, it is important to choose a factory that can design and manufacture extrusion dies —— Hugh aluminum is large aluminum extrusion plant, we are equipped with aluminum extrusion, die design, powder coating, anodizing, CNC, polishing, stamping and welding services.

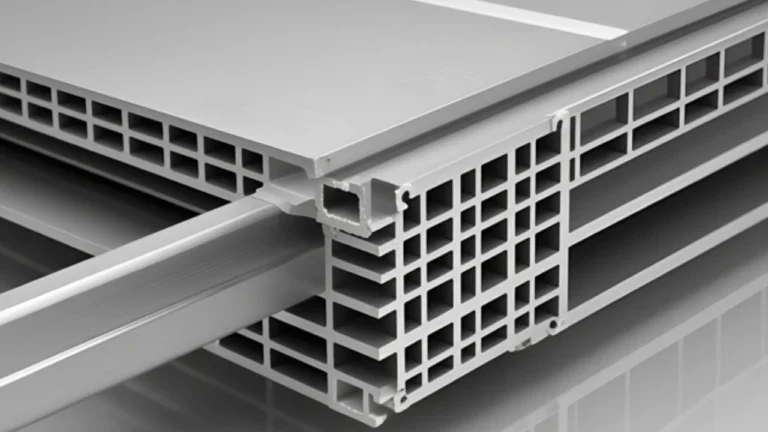

2. Aluminium Extrusion:

Almost all plants have this capability, but the size of aluminum extrusions that can be produced varies. This is because the size of the production line and the tonnage of the press will limit the size of the aluminum extrusion. When you’re looking for aluminum extrusions size:60 x 60, you’ll need to look for factories with extrusion presses of 800 tons or more.

3. Quality Control Function:

Excellent factories will strictly inspect and screen aluminum alloy billets to ensure that their dimensions and quality meet the requirements, as well as clean and degrease them to ensure the smooth running of the extrusion process.

-

Process monitoring:

Factory workers monitor and adjust key parameters such as extrusion speed, pressure and temperature in real time during the extrusion process to ensure stable quality of the profiles.

2. Quality Inspection:

Quality inspectors carry out quality inspection on the aluminum profiles produced. This includes dimensional inspection, surface quality inspection and mechanical property inspection to ensure that the products meet the standards.

4. aluminium extrusions finishing process

Aluminum extrusion plants of a certain size are capable of surface machining. Our common finishes include powder coating, anodizing, PVDF, wood grain, mill finish and anodic electrophoresis. These finishes give aluminum extrusions beautiful colors, and if you want beautiful aluminum building materials, then a factory with these capabilities is your target.

4. Products Price & extrusion plant process fee

As a large aluminium extrusion plant has all the production capabilities. So people tend to think that the price of its products will be competitive. In fact, in the aluminium extrusion market. Smaller aluminium extrusion plants tend to price their products more competitively. This is because its small size and price fluctuations keep labour and material costs lower than those of larger manufacturers. So people should not blindly choose large aluminium extrusion plants when choosing suppliers.

Finally

We have learned about Aluminium Extrusion Factory from the production process of Aluminium Extrusion, the size and type of Aluminium Extrusion Factory, and the price of production. We believe that as the demand for aluminium extrusion products grows, we can experience the convenience of more aluminium products in the future.

Hugh Aluminum is an extruded aluminum plant based in China. We have been in the aluminum extrusion industry for 15 years. We currently have five extrusion lines with production capacity of anodizing, powder coating, CNC, welding and polishing. To learn more please contact us!