What is Aluminum? Discover Its Properties, Uses and History

What is Aluminum?

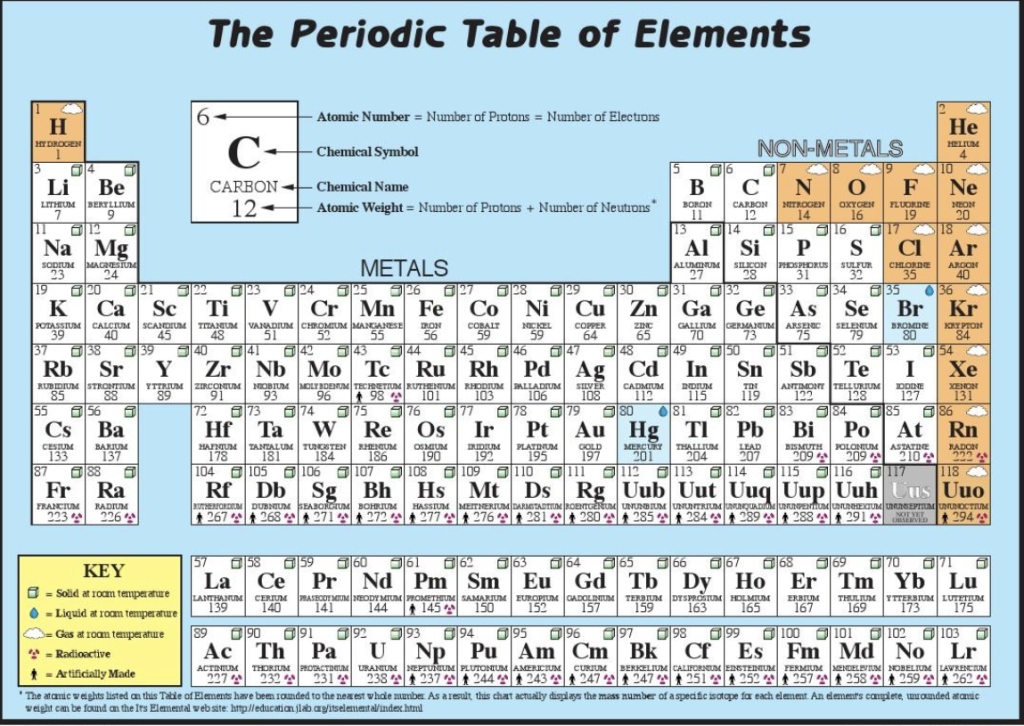

Aluminum is a silvery-white metal and the 13th element on the periodic table. It is the most abundant metallic element in the Earth’s crust and widely used in industries worldwide. However, aluminum does not exist in its pure metallic form in nature due to its high reactivity. Instead, it is found in compounds, such as bauxite, which serve as its primary source.

This metal makes up about 8% of the Earth’s crust, concentrated within the outer 16 kilometers (10 miles). It ranks as the third most common element on Earth, following oxygen and silicon. Its widespread presence and versatility make it essential for countless applications.

The name “aluminum” originates from the Latin word alumen, which referred to potassium alum or potassium aluminum sulfate. This historical connection highlights aluminum’s long-standing importance, even before its modern industrial uses.

This table below shows the chemical and physical properties of aluminum metal:

| Items | Element Properties |

|---|---|

| Chemical Symbols | Al |

| atomic number | 13 |

| atomic weight | 26.9815386(7) |

| physiological state | Silver-white light metal (solid, at room temperature and pressure) |

| density | 2.70 g/cm³(or 2.698 * 10³ kg/m³ at 25℃) |

| melting point | 660.32 °C |

| boiling point | 2327 °C |

| valence | +3 |

| specific gravity | 2.70 (at 20 °C) |

| electron configuration | 1s22s22p63s23p1 |

| Common compounds | Aluminum oxide (Al₂O₃), aluminum chloride (AlCl₃), aluminum sulfate (Al₂(SO₄)₃), etc. |

| Content in the crust | Third (after oxygen and silicon) |

History of Aluminum Metal

Aluminum is a key material today, found in homes, vehicles, electronics, and modern designs. However, 200 years ago, this metal was completely unknown.

The discovery of aluminum began with Sir Humphry Davy, a British physicist and chemist. In the early 19th century, Davy used electrolysis to isolate several new elements, including potassium, sodium, and magnesium. During his experiments, he identified aluminum as a component of aluminum oxide and gave the metal its name.

Later in the 19th century, Danish physicist Christian Oersted advanced the process. He successfully extracted aluminum using electrolysis, marking a major breakthrough. This method of electrolytic reduction is still used today to produce aluminum on an industrial scale.

From obscurity to widespread use, aluminum’s history reflects scientific progress and innovation. Its discovery and refinement have made it one of the most important materials of modern times.

How to Get Aluminum Metal?

Aluminum is extracted through industrial processes that include bauxite treatment, alumina production, and alumina electrolysis. Each step plays a crucial role in transforming raw ore into pure metal.

1. Processing Bauxite

The process begins with bauxite, the main source of aluminum. Bauxite is crushed and ground into fine powder using machines such as jaw crushers or impact crushers. The powdered bauxite is then treated with sulfuric acid in a process called acid leaching. This reaction produces an aluminum sulfate solution. The solution is filtered, heated, and converted into alumina (aluminum oxide), which is the key material for the next stage.

2. Electrolysis of Alumina

Alumina is converted into aluminum through electrolysis. In this process, an electric current passes through molten alumina in an electrolytic cell. Aluminum forms at the cathode (negative electrode), while oxygen is released at the anode (positive electrode). This method, known as electrolytic reduction, is the standard technique for producing aluminum on an industrial scale.

The chemical equation for this reaction is:

This equation shows how electricity splits alumina into aluminum and oxygen gas.

Aluminum extraction relies on precise chemistry and engineering to convert raw ore into a versatile metal used in countless applications today.

Properties of Metal Aluminum

Aluminum is a versatile metal with properties that make it essential in many industries. Here are its key characteristics:

1. Lightweight

Aluminum has a density of 2.7 g/cm³, which is about one-third the density of steel or copper. This low weight makes it ideal for applications where reducing mass is important, such as aerospace, automotive, and construction. Lighter materials improve fuel efficiency, reduce emissions, and lower energy costs.

2. Corrosion Resistance

Aluminum resists corrosion naturally. When exposed to air, it forms a protective layer of aluminum oxide that prevents further damage from moisture or oxygen. This makes it suitable for outdoor use and in environments prone to rusting.

3. Electrical and Thermal Conductivity

Aluminum conducts electricity and heat efficiently. While copper is slightly better at conducting electricity, aluminum offers higher conductivity when measured by weight. Its ability to transfer heat makes it a preferred material for heat sinks, exchangers, and cooling systems.

4. Easy to Process

Aluminum can be shaped using various methods like casting, forging, stamping, and extrusion. It is ductile, meaning it can be stretched into sheets or profiles without breaking. These qualities make aluminum adaptable for manufacturing a wide range of products, from machinery parts to building materials.

5. Non-Magnetic

Aluminum does not react to magnetic fields. This property is valuable in electronics and electrical systems where magnetic interference can disrupt operations.

6. Recyclable

Aluminum is highly recyclable and retains its original properties after recycling. The process requires less energy than producing new aluminum, making it an eco-friendly choice for industries focused on sustainability.

7. Attractive Appearance

Aluminum has a silver-white finish that looks clean and modern. Surface treatments like anodizing or polishing enhance its appearance further, making it popular for decorative applications in buildings and household items.

8. Strength and Durability

Pure aluminum is soft, but alloys like 6082 or 7075 are strong enough for demanding applications such as aircraft parts or structural components. Aluminum alloys also resist impacts and bending, adding durability to their strength.

This combination of lightweight design, corrosion resistance, conductivity, recyclability, and strength makes aluminum one of the most practical metals available today.

Applications of Aluminum Metal

Aluminum is widely used across industries due to its lightweight, corrosion-resistant, and conductive properties. Below are its primary applications:

1. Transportation

Aluminum is essential in transportation because it reduces weight while maintaining strength. Common uses include:

- Car bumper beams

- Vehicle frames

- Aircraft wings and structural parts

- Train tracks

- Traffic signal poles

- Bicycle frames

Its ability to lower fuel consumption and improve efficiency makes it a valuable material for vehicles and infrastructure.

2. Construction

Aluminum is popular in construction due to its durability, low weight, and aesthetic appeal. Examples of its use include:

- Exterior wall panels

- Ceilings and flooring systems

- Handrails and partitions

- Door and window frames

- Roofing systems

- Railings and fences

These applications highlight aluminum’s ability to combine functionality with visual appeal in buildings and structures.

3. Electronics

Aluminum plays a key role in electronics by managing heat effectively. It is commonly used for:

- Heat sinks in computers and appliances

- Cooling systems for electronic devices

- Thermal management components in industrial equipment

Its high thermal conductivity ensures electronic devices operate efficiently without overheating.

Aluminum’s versatility makes it a cornerstone material in transportation, construction, and electronics, supporting innovation and efficiency across industries.

Types of Aluminum Products in Everyday Life

Aluminum is shaped into various products that serve practical purposes across industries and daily life. Below are the main types:

1. Aluminum Plates

Aluminum plates have a thickness between 0.15mm and 2.0mm. They are widely used to create computer casings, doors, and windows. Their combination of strength and lightness makes them ideal for structural and decorative applications.

2. Aluminum Roll Strips

Aluminum roll strips are commonly used in electrical systems. They are essential for winding components like transformers, inductors, and motors. These strips help ensure efficient energy transfer and reliable performance in electrical devices.

3. Aluminum Tubes

Aluminum tubes are available as seamless or welded versions. They are used in construction, transportation, and industrial applications where lightweight yet durable materials are needed. These tubes are often employed for piping systems or structural supports.

4. Aluminum Profiles

Aluminum profiles come in various shapes and sizes to suit a wide range of applications. They are heavily utilized in construction projects, industrial machinery, and other fields requiring adaptable and strong materials.

These aluminum products demonstrate the metal’s versatility and importance in modern life, supporting industries from technology to construction with efficiency and reliability.

Final Thoughts

Aluminum has transformed industries and daily life. As one of the most abundant elements in the Earth’s crust, it is lightweight, corrosion-resistant, and highly versatile. These properties make it essential for products like vehicles, smartphones, and building materials.

Its wide range of applications highlights its importance in transportation, construction, and electronics. Aluminum’s adaptability and efficiency ensure its continued relevance in modern innovation.

For more details about aluminum products, visit Hugh Aluminum, a reliable manufacturer of aluminum extrusions and profiles. Discover how aluminum can support your needs.