What is Aluminum Anodic Electrophoresis Process

The principle of anodic electrophoresis is:

Under the action of a DC electric field, the charged coating particles move to the coated workpiece. This causes the electrophoretic coating deposited on the surface of the aluminum profile to precipitate and form a film.

The electrophoretic coating includes acrylic resins, melamine resins, pigments, solvents, neutralizers, additives and other ingredients.

It will be thermally fixed by means of an elevated bridging layer in the particles, and the shape of the micro-concave coating remains essentially unchanged during baking and the appearance of the film is uniformly formed during the baking process.

It has process steps:

1. Pre-treatment:

First of all, aluminum profiles need to be pre-treated by alkaline cleaning, acid washing or mechanical treatment to remove impurities and dirt from the surface.

2. anodizing:

After the pretreatment is completed, the aluminum profile needs to be anodized to form a protective layer of aluminum oxide. This layer is the basis for electrophoretic coating and also provides hardness and corrosion resistance to the aluminum profile surface.

3. Pre-electrophoretic treatment:

The anodized aluminum profiles are immersed in the pre-electrophoresis solution for pre-electrophoresis treatment. The pre-electrophoresis liquid contains electrophoresis resin particles and appropriate amount of gelling agent to improve the adhesion and uniformity of the coating.

Belows video from Hugh Aluminum shows aluminum anodic electrophoresis processing:

4. Electrophoretic coating:

The aluminum profile after pre-electrophoresis is suspended in the electrophoresis tank as the cathode and electrodeposition is carried out by DC power supply. The electrophoresis resin particles in the electrophoresis solution will be adsorbed from the electrolyte to the surface of the aluminum profile to form a uniform coating under the action of electric field.

5. Curing coating

After the formation of anodic electrophoresis coating, curing treatment should be carried out to improve the hardness and abrasion resistance of the coating. Curing is generally carried out by drying or oven heating, and the curing temperature and time depend on the selected electrophoretic resin.

Its advantages are:

1. excellent corrosion resistance:

After anodic electrophoresis treatment, the surface of aluminum will form a layer of uniform, dense oxide film, which has excellent corrosion resistance, can effectively resist the erosion of acid, alkali, salt and other chemicals, and extend the service life of aluminum.

2. Good decoration and appearance:

Electrophoretic coating has rich color and uniform coating, which can form various beautiful decorative effects. In addition, the electrophoretic coating has good smoothness and gloss, which makes the surface of aluminum more beautiful.

3. Strong adhesion of coating:

In the process of electrophoresis, the coating particles are deposited on the surface of aluminum under the action of electric field, forming a layer of firmly combined coating. This coating has good adhesion with the substrate and is not easy to peel off.

In summary

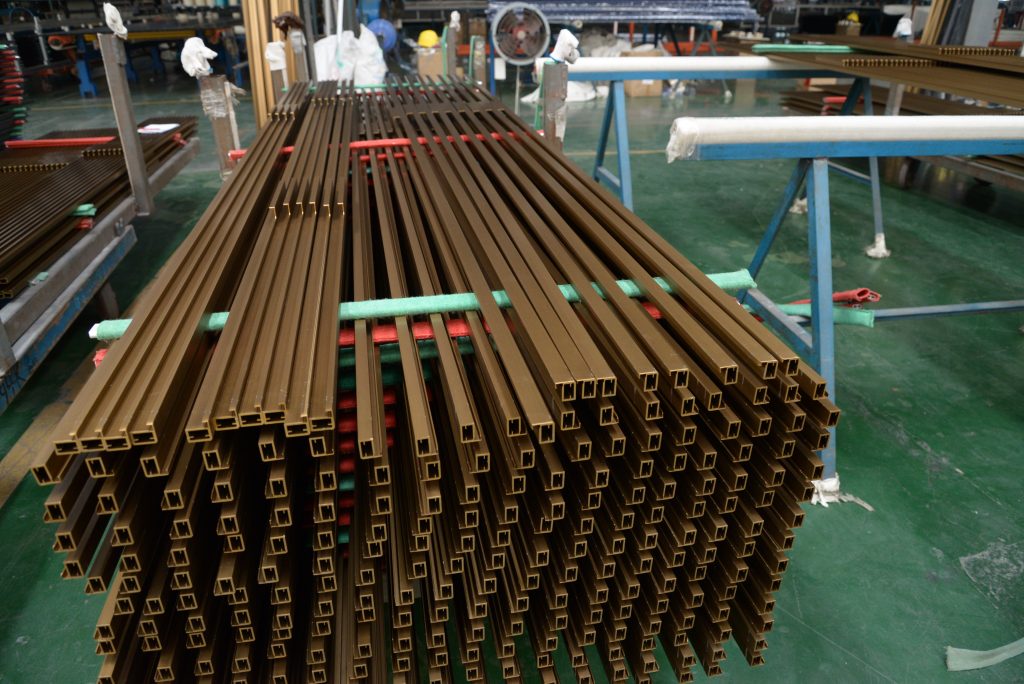

Aluminum anodic electrophoresis is characterized by corrosion resistance, strong hardness and beautiful appearance, so it is widely used in automobile, construction, furniture and other fields.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, anodic electrophoresis,CNC and polishing processing capabilities. We are 15 years experienced aluminum extrusion supplier and can offer you factory price and high quality products.