What is Aluminum F Channel?

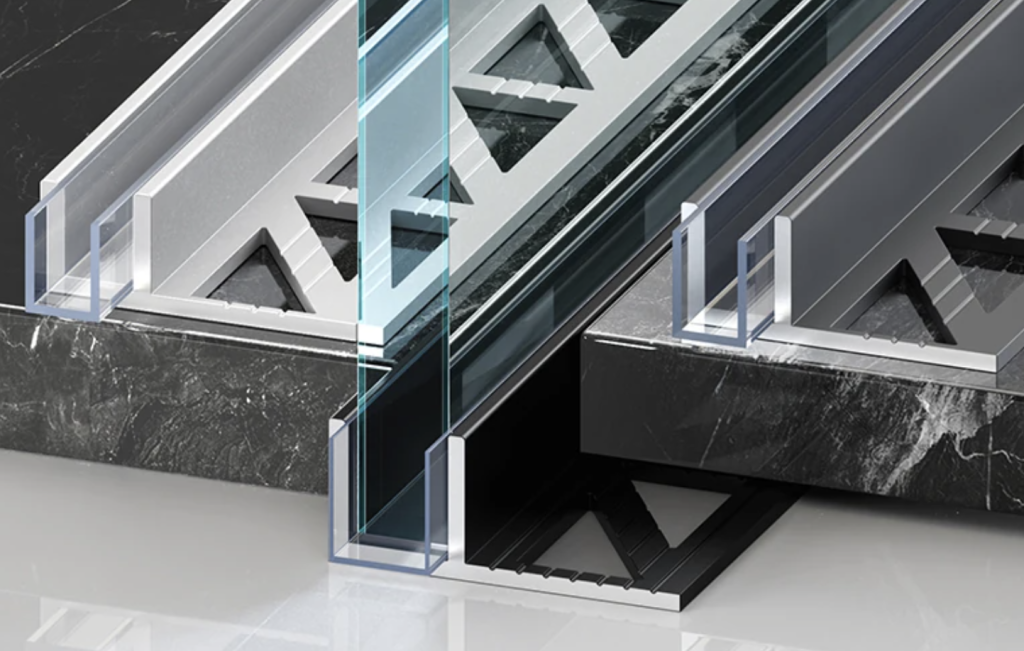

Aluminum F channels are profiles shaped like the letter “F” when viewed from the side. They are widely used in construction due to their practical design and functionality. The groove in the channel securely holds panels, such as wood or glass. The extended side embeds into the floor, providing extra support for the glass or panels.

These channels offer a reliable solution for many applications. Builders and designers often choose aluminum F channels for their strength and stability. Whether for residential or commercial projects, they support various installations.

Is an Aluminum F-Channel Strong?

The F channel is strong enough for everyday use. Its tensile strength reaches 280 MPa, allowing it to withstand impacts and wear from daily activities.

This strength makes F channels suitable for various applications, including construction and electronics. Whether you need structural support or a component for a project, you can trust its durability and performance.

What Makes Aluminum F-Channel So Strong?

Material

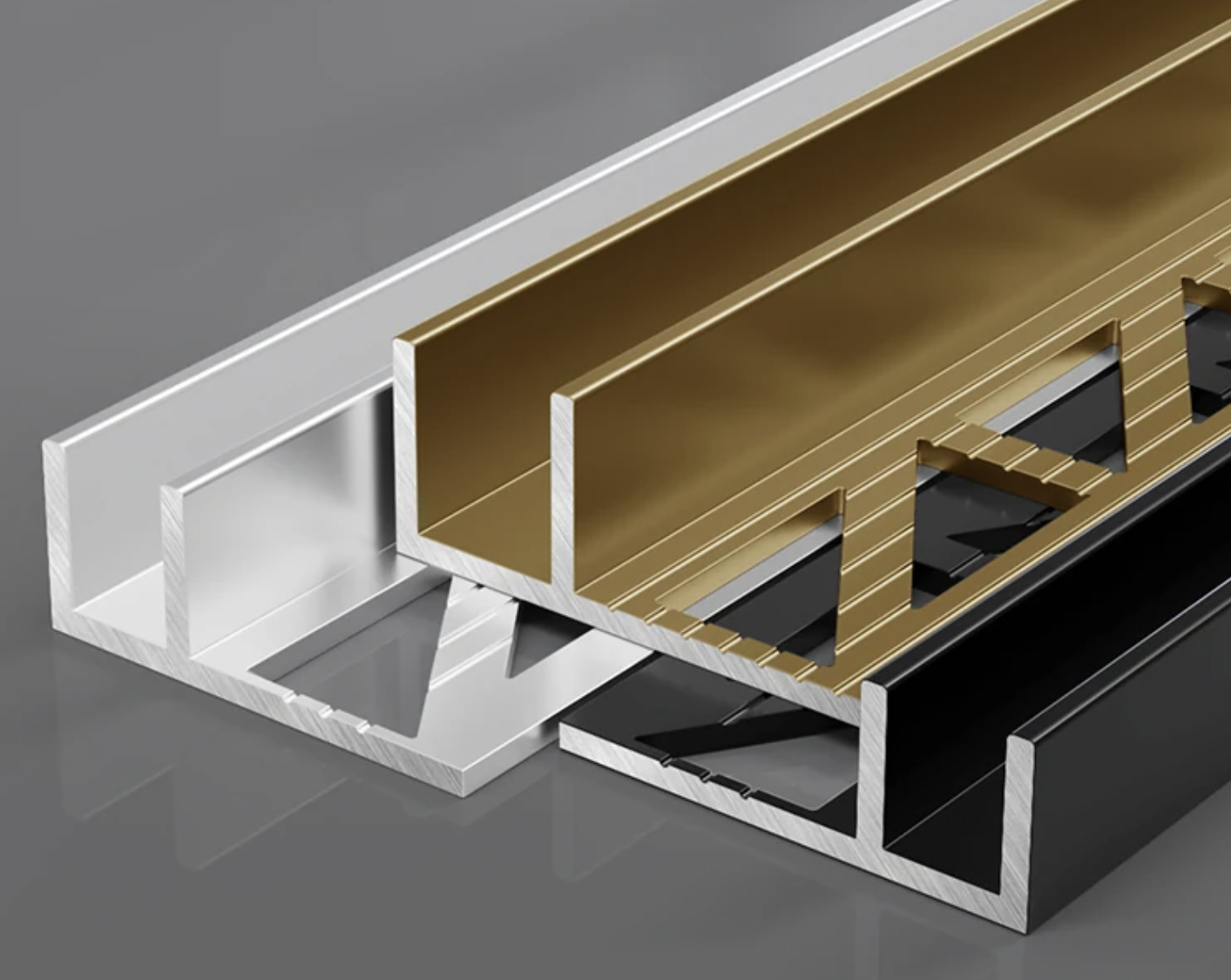

Aluminum F channels are made from aluminum alloys like 6063 and 6061. These alloys are lightweight, corrosion-resistant, and easy to process. The 6063 alloy is particularly strong and offers excellent processing capabilities. It is suitable for applications that require both strength and visual appeal.

Wall Thickness

The wall thickness of an aluminum F channel affects its strength. Thicker walls provide better resistance to compression and bending but also increase material costs. For instance, the wall thickness of a 6063 aluminum alloy F channel can range from 1.2 mm to 2.0 mm, depending on the design and intended use.

Design

The design of F channels impacts their strength as well. A well-structured design optimizes how forces are distributed, enhancing load-carrying capacity. Features like internal arcs and rounded corners improve both stability and appearance.

These factors contribute to the high strength of F channels, making them reliable for various applications in everyday use.

Related reading: Aluminum F-Channel Vs U-Channel

F Channel’s Design and Dimensions

The F-channel has a cross-section that looks like the letter “F.” It consists of three parts: a vertical leg, a horizontal base, and a second vertical leg. This design provides effective support and a mounting surface.

The channel features an opening at the top and a solid bottom. This design allows it to serve as a structural member in buildings or as a conduit for water flow. Its lightweight and strong material make it suitable for various construction applications.

Aluminum F channels come in various sizes. Important dimensions include the height of the profile, the width of the legs, and the thickness of the material. These measurements allow for flexibility in different applications.

The size chart of F-channel by Hugh:

| model | height(mm) | f-channel width(mm) | internal channel size(mm) | wall thickness(mm) |

|---|---|---|---|---|

| 1 | 40 | 60 | 20×20,30×30 | 1.2 – 3.0 |

| 2 | 50 | 100 | 20×20,30×30,40 x 40 | 1.2 – 3.0 |

| 3 | 60 | 200 | 20×20,30×30 40 x40, 50×50 | 1.2 – 3.0 |

| 4 | 65 | 100, 120, 150 | 20×20,30×30, 40×60, 30 x50 | 1.2 – 3.0 |

| 5 | 100 | 100, 120, 150, 200, 250, 300, 400, 500, 600, 800, 1000 | allows below 350 x350 | 0.8 – 3.0 |

| other | customized | customized | customized | customized |

Features of Aluminum F Channel

Lightweight and Durable

The F channels are lightweight due to the low density of aluminum alloy. This material resists corrosion and abrasion, making it durable against damage.

Excellent Waterproof Performance

The F channels provide excellent waterproof performance. They can stay submerged in water for long periods without any effect on their structure. These channels maintain their appearance in humid environments, making them suitable for use in bathrooms and toilets.

Easy to Process

Aluminum F channels are easy to cut, drill, and bend. This flexibility allows them to fit various applications, such as in bathrooms, bedrooms, bookcases, and tables. Their adaptability makes them a practical choice for many projects.

What is an Aluminum F-Channel Used for?

Construction Field

Aluminum F channels are commonly used in construction for curtain walls, roofs, doors, and windows. Their lightweight and corrosion-resistant properties make them popular choices. For example, aluminum channels act as brackets for large curtain wall structures, providing stability and visual appeal. Additionally, aluminum gutters serve as effective rainwater drainage systems for roofs. Their large cross-section allows water to flow freely, preventing buildup.

Electronics

In the electronics sector, the F-channels are used for cable trays and cable channels. Their excellent conductivity and lightweight durability make them ideal for these applications. In cable channels, aluminum channels provide stability and safety for electrical wiring.

Transportation

In transportation, aluminum F channels are utilized in subway and highway projects. Their lightweight and strong features make them suitable for barriers and guardrails. For instance, they can be used as the base material for highway guardrails, offering strength and reliability.

The F channels serve various industries effectively, enhancing functionality and safety in construction, electronics, and transportation projects.

Final Thoughts

Aluminum F channels are construction materials made by extruding aluminum alloy. They serve a wide range of applications in various fields. Their lightweight, durable, rust-resistant, and easy-to-process features make them suitable for many uses.

These channels are valuable in construction, electronics, and transportation. Their strength and versatility meet the needs of both professionals and DIY enthusiasts. Whether you are building a structure or working on a project, the F channels can provide reliable support and functionality.

Read more: The Ultimate Comparison of Aluminum Channels