What is aluminum profile anodic electrophoresis surface treatment

Principle of Electrophoresis:

Electrophoresis is the electrophoretic coating in the cathode and anode, applied to the role of voltage, the charge of the paint ions move to the cathode, and with the cathodic surface of the alkaline effect of the formation of insoluble substances, deposited on the surface of the workpiece. Usually aluminum profiles are electrophoretically coated by conducting electricity from both sides.

Anodic electrophoresis process:

1. Electrolysis (decomposition)

In the cathode reaction initially for the electrolysis reaction, the generation of hydrogen and hydroxide ions OH, this reaction causes the cathode surface to form a highly alkaline boundary layer, when the cation and hydroxide role of insoluble substances, coating film deposition, the equation is: H2O → OH + H

2. Electrophoretic movement (swimming, migration)

Cation resin and H+ under the action of electric field, move to the cathode, and anion to the anode mobile process.

3. Electrodeposition (precipitation)

On the surface of the coated workpiece, the cation resin and the cathode surface alkaline action, neutralization and precipitation of non-deposited material, deposited on the coated workpiece.

4. Electro-osmosis (dehydration)

The coating film on the surface of paint solid and workpiece is translucent, with most capillaries, water is exuded from the cathode coating film, and under the action of electric field, it causes the coating film to dehydrate, and the coating film is adsorbed on the surface of the workpiece, and completes the whole electrophoresis process.

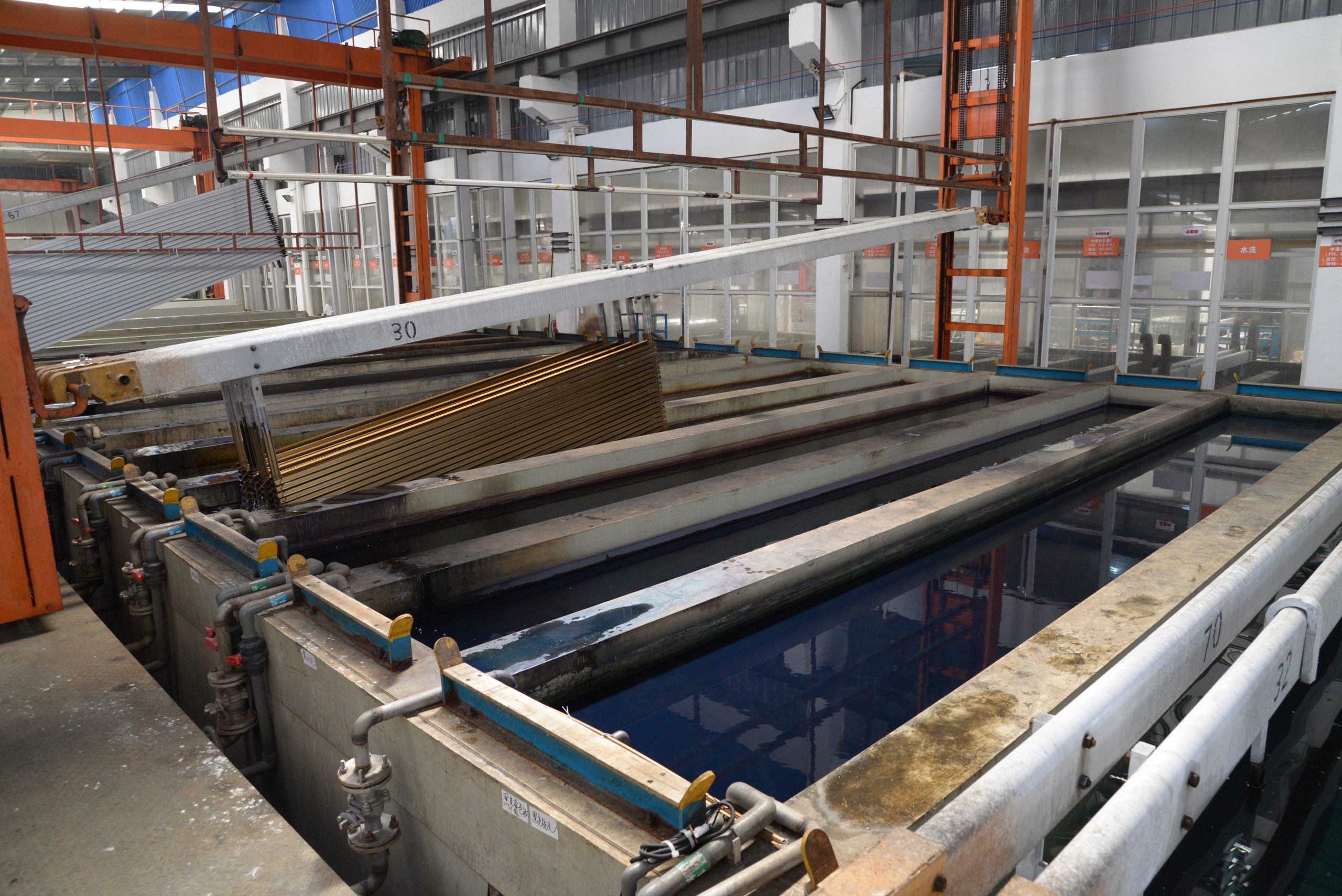

Here are the Electrophoresis process from Hugh Aluminum;

In Summary:

Advantages and disadvantages of anodic electrophoresis surface treatment process

The electrophoretic paint film has the advantages of plump. even, flat and smooth coating, and the hardness, adhesion, corrosion resistance. Impact performance and penetration performance of the electrophoretic paint film are obviously better than those of other coating processes.

Its biggest defect is that the color of electrophoresis is relatively single, there are only a few colors (silver-white, champagne, golden yellow, black, imitation stainless steel color).

Secondly, electrophoresis color is easy to produce color difference.

Hugh aluminum is an Extruded Aluminum manufacturer, we have the ability to produce anodic electrophoresis, anodic oxidation and powder coating surface treatment and modern aluminum extrusion line. Our aluminum profile surface treatment meets ISO standards to meet your aluminum profile production and surface treatment needs.