What is Aluminum U-Channel?

Aluminum U-channel is a great and strong metal profile used in many industries. The U shape gives it strength and stability so it’s perfect for construction, manufacturing, and transportation.

In this article, we will go over the features, and benefits of aluminum U-channel and why it is important in modern projects.

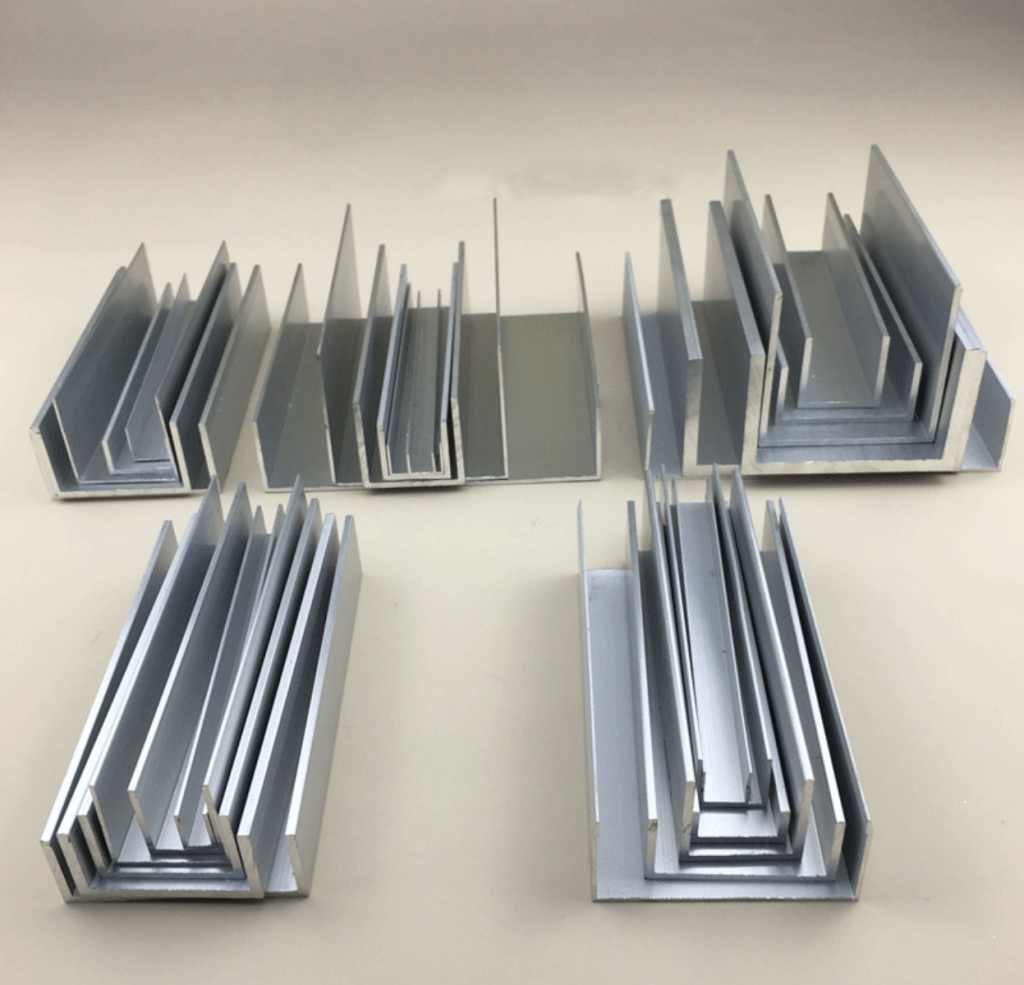

What is a U-shaped Aluminum Channel?

Aluminum U-channel is a metal profile with a U-shaped cross-section. It is made from aluminum alloy and is widely used in construction and manufacturing.

This material is lightweight yet strong. Its strength allows it to support heavy loads while remaining easy to handle. Additionally, aluminum resists corrosion, making it suitable for both indoor and outdoor applications.

Aluminum U-channels serve various purposes. They are often used for support structures, reinforcement, and even decorative elements. You can find them in window frames, door frames, railings, and more. Their versatility makes them ideal for many projects.

The demand for aluminum U-channels continues to grow as industries evolve. They can be easily cut, drilled, or welded to fit specific needs. This flexibility makes them valuable in many sectors.

Read more: Aluminum Channel Types and Their Uses

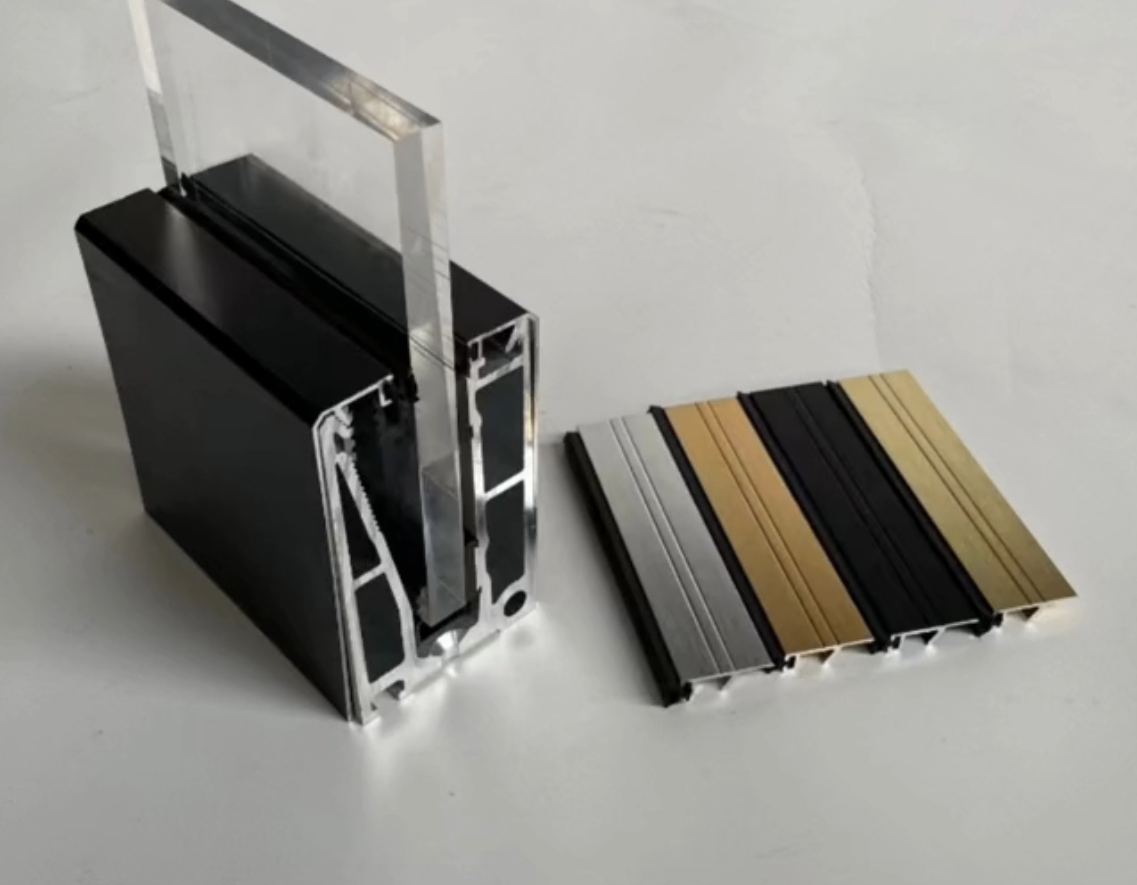

U-Channel Supports Customization

U-channels can be customized to meet specific construction needs or protect items. Their depth and width can be adjusted based on the design of the aluminum extrusion die. This flexibility is crucial for builders.

For example, if a contractor needs a water diversion channel or a U-channel to clamp a board, manufacturers can modify the product to fit those requirements. This ability to adapt makes U-channels important in construction and industrial applications.

Customization provides solutions that fit project specifications perfectly. Whether it’s a specific size or function, U-channels can change to suit the task. This not only saves time but also improves the effectiveness of the final product.

The customization of U-channels is a significant benefit. It allows builders and manufacturers to create solutions that meet their exact needs. So, whether you’re diverting water or securing materials, customized U-channels are ready to help.

Typical Sizes of Aluminum U-channels

Aluminum U-shaped channels typically come in lengths of 6 to 12 meters. You can customize these channels for specific projects, providing flexibility for various applications. If you need a size that isn’t listed, please reach out for options that fit your needs.

- Widths: 12.7 mm (1/2”) to 76.2 mm (3”)

- Heights: 12.7 mm (1/2”) to 50.8 mm (2”)

- Thicknesses: 1 mm (0.04”) to 6.3 mm (1/4”)

This table shows specifications for aluminum U-channels made by Hugh Aluminum. Many other sizes and types are available in the market. For pricing and additional sizes, please contact us directly.

| u channel model | width (mm) | height (mm) | wall thickness (mm) |

|---|---|---|---|

| U-12 | 10 | 10 | 1.5 |

| U-13 | 15 | 15 | 1.5 |

| U-14 | 20 | 20 | 1.5 |

| U-15 | 25 | 25 | 1.5 |

| U-16 | 30 | 30 | 1.5 |

| U-17 | 40 | 40 | 1.5 |

| others | customized | customized | customized |

Advantages of Aluminum U-Channel

The extruded U-shaped channels offer many benefits. They are lightweight, strong, corrosion-resistant, durable, and recyclable. These features make them an excellent choice for construction and manufacturing projects.

Lightweight

The extruded U-channels are light. Their density is only one-third that of iron, making them easy to carry and handle.

High Strength

Aluminum U-channels have strength similar to steel. This high strength allows for lighter products and lower costs without losing durability.

Good Corrosion Resistance

Aluminum U-channels resist corrosion and oxidation. They perform well in harsh environments and do not rust easily, making them suitable for outdoor applications.

Durability

Aluminum U-channels are very durable and need little maintenance. The oxide film on their surface protects them from corrosion and seawater. Cleaning them twice a year keeps them in good shape.

Recyclable

When it’s time to replace an U-channel, recycling is a smart choice. Aluminum is 100% recyclable. Even formed aluminum can be melted down and reused as a building material, helping to protect the environment.

Disadvantages of U-shaped Aluminum

The extruded U-channels have advantages, but their higher price and potential for damage are key drawbacks. Consider these factors when deciding if U-channel extrusions are the right choice for your project. Balancing cost and durability can lead to better outcomes in construction and manufacturing.

Higher Price

Aluminum U-channels are generally more expensive than other materials, such as stainless steel and various building options. This higher cost can impact project budgets.

Easily Damaged

U-shaped aluminum channels are softer than some alternatives. They can bend or deform under strong pressure, making them more vulnerable to damage. Careful handling during installation and use is important to avoid issues.

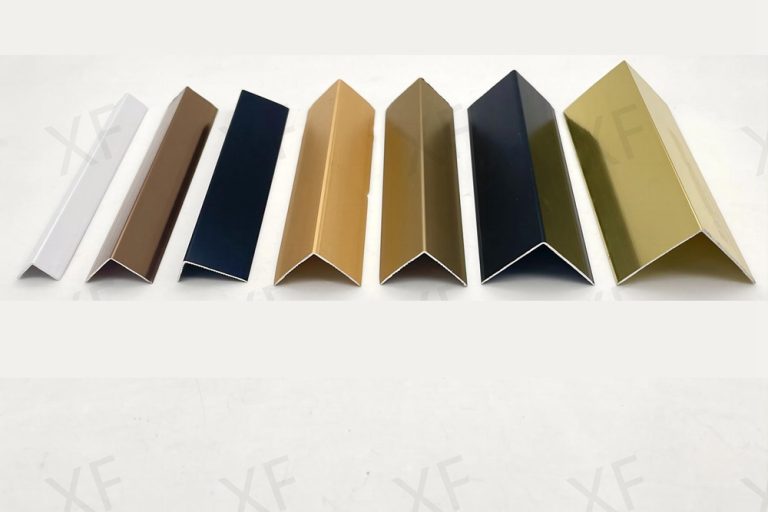

Finishes of Aluminum Channel

The aluminum channel extrusions come in several finishes, each with specific benefits. The mill finish is simple but less protective, while anodized and powder-coated options provide better durability and aesthetic appeal. Choose a finish based on your project needs and environmental conditions.

Mill Finish

The mill finish is the standard option for aluminum channels. It has a silver or metallic look. However, this finish provides little protection against corrosion. If used outdoors or near the sea, it may rust over time.

Anodized Finish

Anodizing improves durability and adds color options. This process attaches color to the surface using an electrical charge. By adjusting the discharge time, manufacturers can create different colors. Anodized finishes resist wear and corrosion better than mill finishes.

Powder Coating

Powder coating offers extra protection and a variety of colors. It is the most common finish for aluminum channels. This coating enhances appearance and increases resistance to scratches and environmental damage.

Applications for Aluminum Channel

Aluminum extruded channels are widely used in several important areas:

- Transportation Equipment: They are used in vehicles for storage compartments and drainage systems in trains.

- Construction: In construction, aluminum channels support glass U railings, LED light bar decorations, and wall panel protection. Their strength and light weight make them ideal for these uses.

- Electronic Equipment: Aluminum channels also protect electronic parts. They are commonly found in cases for batteries and other electronic components.

The extrusion channels serve diverse functions in transportation, construction, and electronics. Their versatility makes them a valuable choice for many projects.

Conclusion

Aluminum U-channel is a lightweight, strong, and corrosion-resistant material. It has many applications across different fields. Although it is relatively expensive and can be easily damaged, its advantages often make it a preferred choice.

Its portability and durability contribute to its popularity in construction, transportation, and electronics. If you need a reliable solution, aluminum U-channel is a smart option to consider.