What is Heat Sink

Introduction

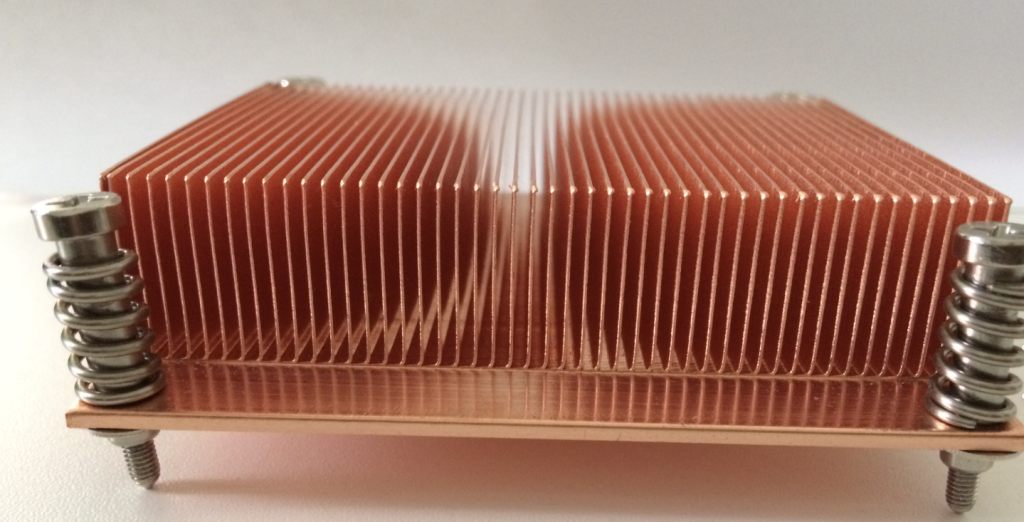

Heat sink is a kind of device to dissipate heat to the easy-to-heat electronic components in electrical appliances. It is usually made of metal materials such as aluminum alloy, brass or bronze.

It comes in various shapes, such as plate, sheet or multi-piece. The main function of the heat sink is to transfer heat from the heat source to the air by increasing the surface area to achieve the purpose of heat dissipation.

Working Principle of Heat Sinks:

The working principle of heat sink is based on the principle of heat transfer. That is, the transfer of heat must rely on heat-conducting materials and heat transfer medium. The heat sink itself is made of thermally conductive metal and transfers the heat source attached to the radiator or other heat sink to it.

And through a higher surface area, the heat is transferred to the environment. At the same time, heat transfer can be accelerated by forcing the flow of gas through the heat sink at the right speed.

Application of heat sink:

1. Electronic equipment field:

Heat sinks are widely used in the field of electronic equipment. Such as CPU, GPU, chipset, power supply, hard disk and other electronic devices. These electronic devices will generate a lot of heat during operation, if the heat dissipation is not timely, it will seriously affect the performance and life of the equipment. Heat sinks dissipate heat by emitting heat to achieve the effect of heat dissipation and improve the stability and reliability of the equipment.

2. Automotive field:

The use of heat sinks in the automotive field is mainly concentrated in the engine, transmission, braking system and other parts. The automobile will produce a large amount of heat when traveling. If it can not be emitted in time, it will lead to engine overheating, coolant boiling and other problems. Therefore, the design and material selection of automobile heat sink is very important, which directly affects the performance and life of the car.

3. Mechanical field:

Heat sinks are also widely used in the mechanical field, such as aircraft engines, high-speed train engines, deep-well drilling rigs and ship nacelles, etc., in order to better cool the engine and transmission system.

4. LED lighting field:

LED lamps and lanterns, etc. also need the aid of heat sinks, because the high brightness of the LED light-emitting diode will also produce heat when working, no heat can not effectively extend the service life of the LED.

5. Optoelectronic device field:

Such as lasers, optical communication equipment, etc. will also often have the application of heat sinks.

Advantages of heat sink:

1. Good heat dissipation effect:

The main function of heat sink is to dissipate heat, by increasing the heat dissipation area and thermal conductivity, it can effectively dissipate heat to the surrounding environment, thus reducing the temperature of the equipment.

2. Improve equipment stability:

As the heat sink can keep the equipment running at a lower temperature, this helps to avoid performance degradation or damage caused by overheating of the equipment, thus improving the stability and reliability of the equipment.

3. Extend equipment life:

Heat sinks can effectively reduce the temperature of the equipment and minimize the damage to the equipment due to overheating, thus extending the life of the equipment.

4. Wide application:

Heat sinks are not only used in the field of electronic equipment, but also widely used in automobiles, machinery, LED lighting, optoelectronic devices and other industries, with strong versatility and adaptability.

Disadvantages of heat sinks:

1. Higher cost:

Heat sinks usually require the use of high-performance heat-conducting materials and complex processing techniques to manufacture, and are therefore relatively costly. This may increase the manufacturing cost and selling price of the device.

2. Higher weight and volume:

In order to achieve better heat dissipation, heatsinks usually need to be designed to be larger and heavier, which may increase the overall weight and volume of the device, which may be a disadvantage for the pursuit of thin and light portable devices.

3. Inconvenient to install and maintain:

Heat sinks usually need to be fixed inside or outside the device, which may be cumbersome to install and maintain. If the heatsink fails or is damaged, it may be necessary to disassemble the device or replace the entire cooling system.

4. May generate noise:

Some heatsinks may generate noise during operation, especially under high load or high temperature environments. This may cause some disruption to the user.

Overall

The main function of a heatsink is to diffuse the heat generated through its surface into the external environment, ensuring that the temperature of the equipment or parts does not become too high during normal operation and helping to extend the life of the equipment.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including all type of aluminum heat sink:LED,PCB, Server Hosting,Power heat sink