What is the Differences Between Aluminum Round and Square Pipes?

Aluminum round and square pipes differ in shape, performance, applications, processing, and cost. Below is a clear and concise comparison to help you decide which type suits your needs.

Shape

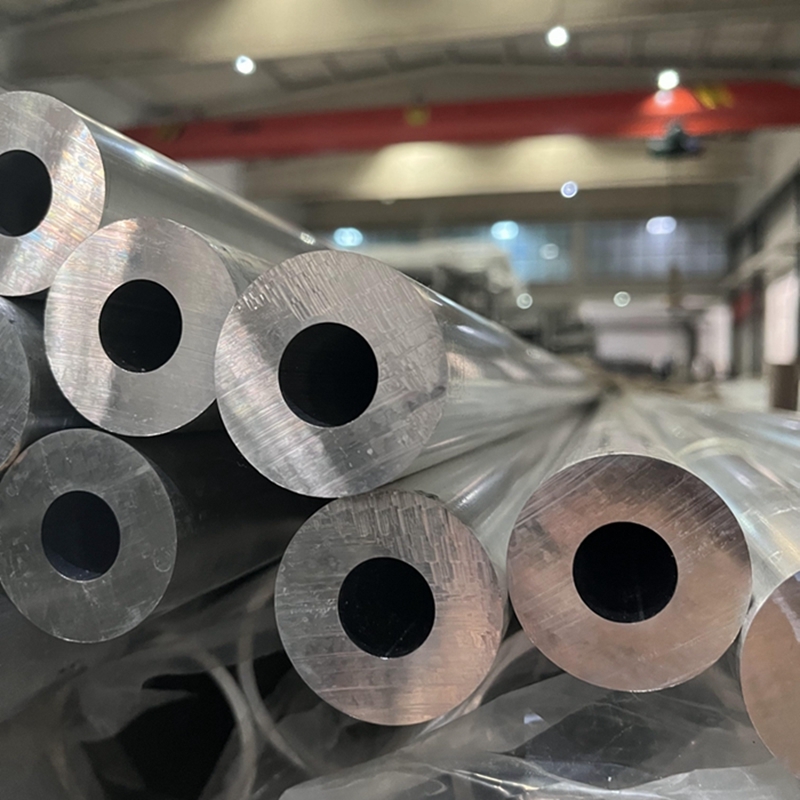

- Round Pipe: Has a circular cross-section. It is smooth and symmetrical, with no edges or corners.

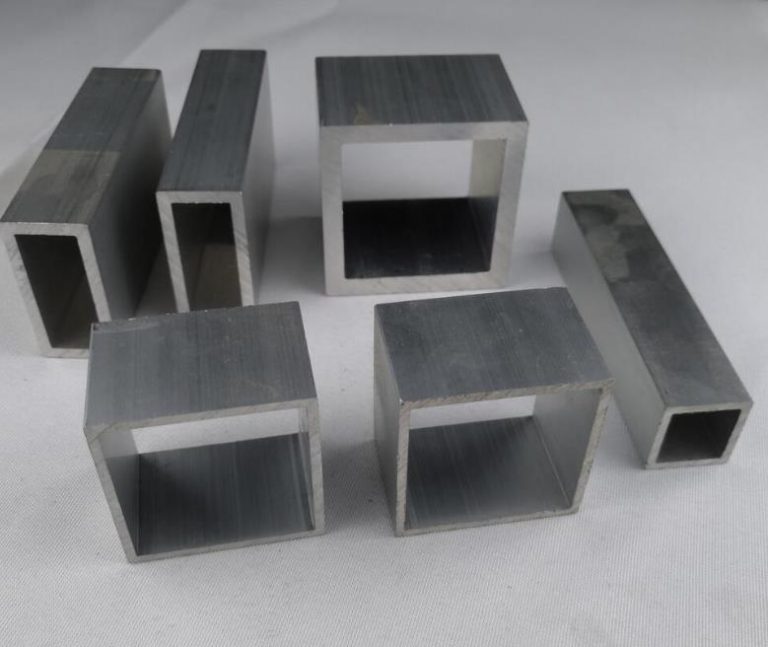

- Square Pipe: Features a square or rectangular cross-section with sharp edges and defined corners.

Performance

- Round Pipe: Its circular design distributes pressure evenly under internal or external loads. This makes it strong for bending, twisting, and handling stress.

- Square Pipe: Its angular structure provides strength for compression and bending in specific directions. However, stress can build up at the corners when exposed to twisting or complex forces.

Applications

- Round Pipe: Commonly used for transporting liquids or gases due to its pressure-handling ability. It also works well in rotating machinery parts and is popular in decorative and construction projects because of its clean, symmetrical look.

- Square Pipe: Often used in construction, furniture, and machinery where stable frames or support structures are needed. It’s ideal for making shelves, railings, and frameworks.

Processing and Connection

- Round Pipe: Easy to bend, cut, and weld. It supports various connection methods like welding or threaded connections.

- Square Pipe: Requires attention to corner details during processing. Common connection methods include welding and bolting.

Cost

Round pipes are generally easier to manufacture than square pipes of the same cross-sectional area, which may make them less expensive. However, costs vary based on material quality, production methods, and market demand.

Final Thoughts

Choosing between aluminum round and square pipes depends on your project’s requirements. Round pipes excel in pressure handling and aesthetic applications, while square pipes shine in structural stability and frame construction. Evaluate your needs carefully to make the best choice!

Related products:

Aluminum round tubes

Aluminum square tubes

Aluminum extrusion tubes

Learn more:

Aluminum tubes comparison complete guide