What is the general precision of aluminum extrusion?

What is the general precision of aluminum extrusion?

The extrusion precision of general aluminum extrusion will be affected by several factors, including extrusion equipment, the precision of the tooling, process parameters and so on. The following is the information about the general aluminum profile extrusion precision:

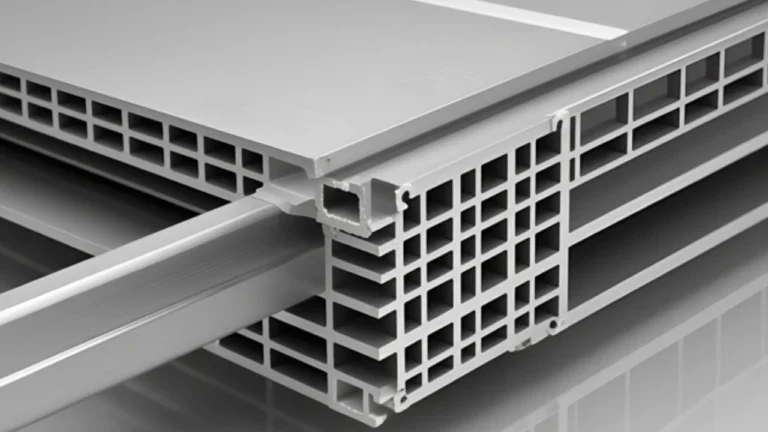

1. Dimensional tolerances:

The smallest wall thickness of aluminum profile is only 0.4mm, and its tolerance requirement is usually ±0.04mm. this strict tolerance requirement reflects the precision of the extrusion process.

For some special small precision aluminum profiles, their dimensional tolerances may be further reduced to between ±0.04 and ±0.07mm.

aluminum processing video:

2. Extrusion technology and equipment:

Precision extrusion technology for aluminum profiles relies on high-precision equipment and tooling. For example, the cutting precision of aluminum profiles can reach ±0.1mm by using VIGMA double knife cutting technology imported from Germany.

In order to improve the service life of the aluminum profile extrusion processing dies and ensure the surface quality of the products, the roughness of the working belt of the die cavity needs to reach 0.8-0.4μm, and the roughness of the die plane needs to reach below 1.6μm.

In order to improve the precision of aluminum extrusion, it may be necessary to use new special equipment, such as CNC lathes, CNC machining centers, and slow-wire processing and other high-precision processing equipment.

3. Tooling requirements:

The rigidity, heat resistance and wear resistance of the mold have a direct impact on the dimensional accuracy of the extruded products. Die needs to be maintained at high temperatures and pressures are not easy to deform, and has a high heat resistance.

Die nitride layer hardness and thickness is also a key factor affecting wear resistance, usually requires nitride layer hardness of 1150HV or more.

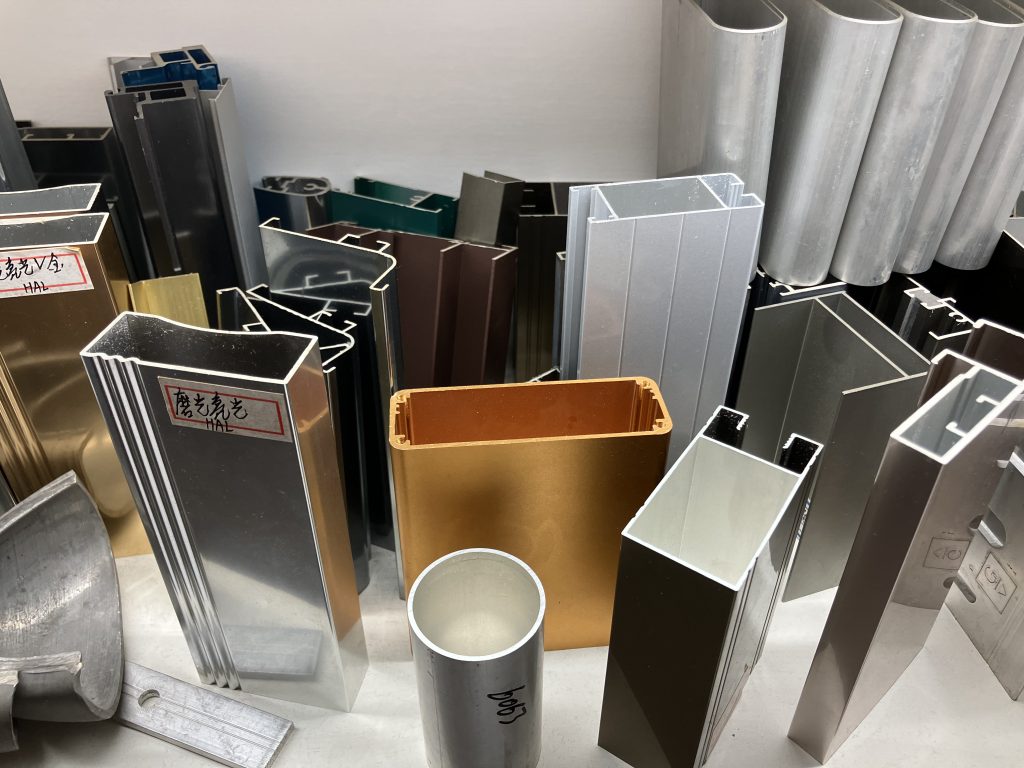

4. Material selection:

Different types of aluminum alloys exhibit different characteristics in the extrusion process, and the selection of suitable aluminum alloy materials is crucial to ensure extrusion accuracy.

For example, low and medium strength aluminum alloy (such as A1050, A1100, A3003, A6061, A6063). Compare with medium and high strength aluminum alloys (e.g. A5083, A2024, A7075). They may differ in extrusion precision.

Summarize the above

The extrusion precision of general aluminum profiles can reach a high level, especially in the case of using advanced equipment and tooling. The specific extrusion precision may vary depending on the specification of the profile, the technical level of the manufacturer and the process parameters used.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We have extrusion, powder coating, anodizing, CNC and polishing processing capabilities. We are 15 years experienced aluminum extrusion supplier and can offer you factory price and high quality products.