What is the Load-Carrying Capacity of the Aluminum Square Tube?

The load-carrying capacity of aluminum square tubes depends on several factors, including material, specifications, shape, and environmental conditions. Below is a clear and detailed explanation:

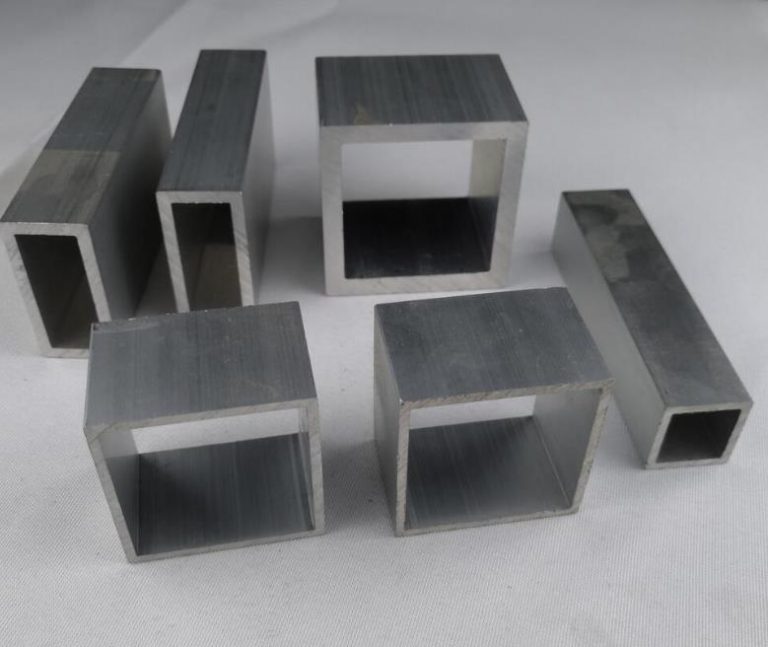

Related products: Extruded aluminum tubes

Material and Specifications

The material and dimensions of the aluminum square tube are key factors in determining its load capacity.

- Material Strength: Aluminum alloys have tensile strengths ranging from 10,000 psi to 75,000 psi, depending on the grade. This means each square inch can withstand between 10,000 and 75,000 pounds before breaking.

- Example: A 60mm x 60mm aluminum square tube with a 2.5mm wall thickness can support approximately 2.01 kN (204.8 kg) under normal conditions. Actual performance may vary based on specific use cases.

Shape and Connection Method

The shape and how the tube is connected also affect its strength:

- Shape Design: Curved or uniquely shaped tubes may have different load-bearing characteristics compared to standard square tubes.

- Connection Methods: Welding, riveting, or bolting impacts overall strength. Properly executed connections improve load capacity.

Environmental Conditions

External factors such as temperature, humidity, and dynamic loads influence the tube’s performance:

- Temperature: High temperatures can weaken aluminum over time.

- Dynamic Loads: Repeated impacts or vibrations may reduce the tube’s ability to carry weight effectively.

How to Calculate Load-Bearing Capacity?

Accurate calculations are essential to determine the load-carrying capacity of aluminum square tubes. Follow these steps:

Step 1: Define Parameters

- Side Length (a): The length of one side of the square cross-section.

- Wall Thickness (t): The thickness of the tube walls.

- Length (L): The total length of the tube.

Step 2: Calculate the Cross-Sectional Area and Moment of Inertia

Cross-Sectional Area (A):

Moment of Inertia (I): For square tubes, use

Step 3: Check Load Capacity

Stress Check: Ensure that compressive or tensile stress remains below the allowable stress for the material.

Stability Check: For long or thin tubes under axial pressure or bending loads, use Euler’s formula:

Where:

- P_{cr} = critical pressure

- E = modulus of elasticity

- I = moment of inertia

- K = length factor (depends on support conditions)

- L = length

This formula works for simple rectangular sections but may require adjustments for complex designs.

Conclusion

The load-carrying capacity of aluminum square tubes depends on multiple factors such as material strength, dimensions, shape, connection methods, and environmental conditions. Accurate calculations are critical for safety and reliability in applications. For high-stakes projects, consulting a professional engineer is recommended to ensure precise measurements and safe designs!

Read more:

Aluminum tubes strength and durability complete guide

How to calculate the strength of aluminum square tubes?