What is the Strength of the Aluminum Tube?

Aluminum tubing is a widely used material in construction, industrial equipment, and bridges. However, not all aluminum tubes are suitable for every project, as they can fail under excessive loads. Understanding their strength and the factors that influence them is essential for safe and effective use.

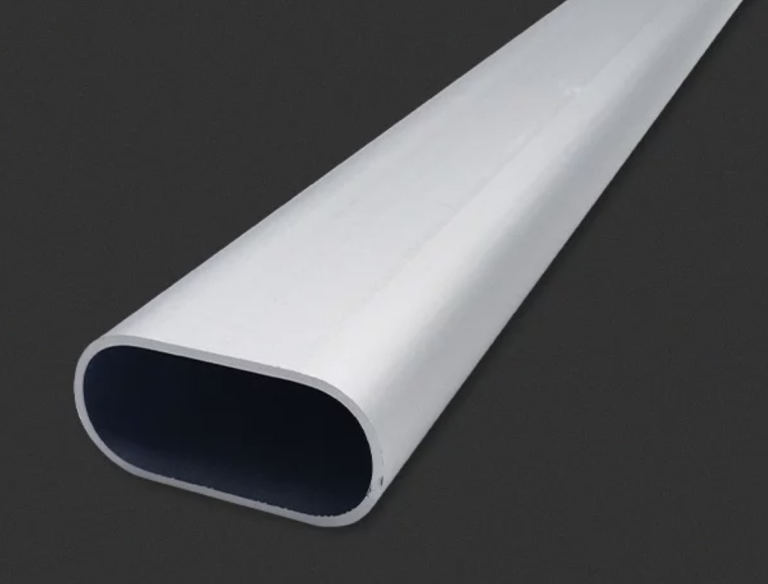

Related products: Extruded aluminum tubes

Strength of Aluminum Tubes

The strength of aluminum tubes depends on the alloy and tempering process used. Below are common aluminum grades with their strength properties:

6061-T6 Aluminum

- Tensile Strength: ~290 MPa (42,000 psi)

- Yield Strength: ~241 MPa (35,000 psi)

- Elongation: 8-10%

6063-T5 Aluminum

- Tensile Strength: ~186 MPa (27,000 psi)

- Yield Strength: ~145 MPa (21,000 psi)

- Elongation: 8-12%

6063-T52 Aluminum

- Tensile Strength: ~207 MPa (30,000 psi)

- Yield Strength: ~145 MPa (21,000 psi)

- Elongation: 8-12%

Factors Affecting Aluminum Tube Strength

- Alloy Composition – Different alloys include elements like magnesium, silicon, and copper that affect strength and durability. For example, silicon increases strength, while magnesium improves corrosion resistance.

- Tempering Process – Heat treatment significantly impacts strength. Common tempers include T5, T6, and T52, with T6 being the strongest. For instance, 6063-T5 tubes are stronger than standard 5052 alloy tubes.

- Dimensions – Wall thickness and cross-sectional size determine load capacity. Thicker walls and larger cross-sections provide greater strength. Insufficient wall thickness can lead to fractures or deformation under load.

- Manufacturing Quality – The extrusion process, welding quality, and post-processing affect the tube’s mechanical properties. High-quality manufacturing ensures consistent strength and durability.

Practical Considerations

- Load Type – Identify whether the tube will face tensile, compressive, shear, or bending loads. Each type interacts differently with the material’s properties. For example, bending loads can reduce performance significantly.

- Environmental Conditions – Aluminum resists corrosion but may degrade in extreme environments like seawater or acidic conditions. Prolonged exposure to high temperatures can also weaken the material. Regular maintenance can help protect aluminum tubes in harsh environments.

- Safety in Design – Engineers often apply safety factors to account for uncertainties in material properties and load estimates. If a project demands higher-strength materials, aluminum may not always be the best option.

Conclusion

The strength of aluminum tubing varies by alloy type, tempering process, and dimensions. Alloys like 6061-T6 and 6063-T5 offer a balance of strength, weight, and corrosion resistance for many applications.

When selecting aluminum tubes for a project, consider load requirements, environmental factors, and manufacturing quality to ensure optimal performance and safety.

Read more: Aluminum Tubes Strength and Durability Complete Guide

For high-quality aluminum tubes or bulk purchases, contact Hugh Aluminum—a trusted manufacturer with 14 years of experience in designing and producing aluminum products.