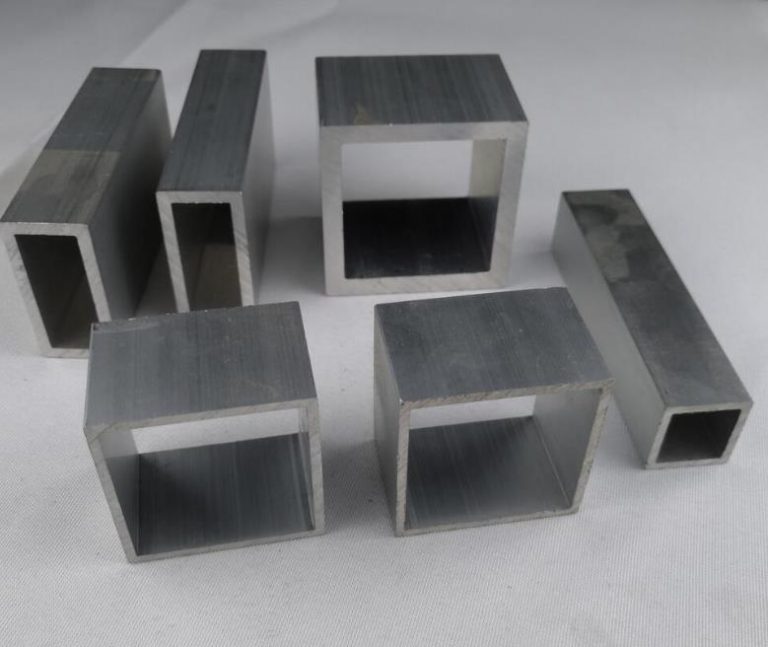

What is a Thin-Walled Extruded Aluminum Rectangular Tube?

A thin-walled extruded aluminum rectangular tube is a lightweight aluminum tube with a rectangular cross-section. Its defining feature is its thin walls, which reduce weight compared to traditional rectangular tubes.

More products: Aluminum Extrusions Tubes

What Does “Thin-Walled” Mean?

“Thin-walled” refers to materials with a wall thickness of less than half their width or diameter. For example:

- In piping, thin walls typically range from 0.6mm to 2.0mm.

- A general rule is that if the wall thickness is less than 1mm, it qualifies as thin-walled.

A more technical definition uses the process/wall thickness ratio (L/t):

- If the distance (L) from the mold’s main flow path to the farthest point of the finished product divided by the wall thickness (t) exceeds 150, it is classified as thin-walled.

Advantages of Thin-Walled Aluminum Rectangular Tubes

- Lightweight: Thin walls reduce material usage, making these tubes lighter than traditional options. The reduced weight simplifies installation and dismantling. For example, they are ideal for indoor ceiling applications where lower weight reduces installation costs.

- Cost-Effective: Thin-walled tubes are cheaper because they require less aluminum. Their affordability makes them competitive in budget-friendly markets and projects.

- Easy to Process: The reduced wall thickness allows for easier machining and fabrication. Processes like drilling, cutting, and stamping require less pressure, lowering production costs. Additionally, anodizing thin walls uses less current, further reducing finishing costs.

Limitations of Thin-Walled Aluminum Rectangular Tubes

- Limited Strength: Thin walls provide less strength, making these tubes unsuitable for applications requiring high pressure or heavy loads. Always evaluate their strength for specific use cases.

- Welding Challenges: Welding thin-walled aluminum requires special techniques and equipment due to its delicate structure. This increases production complexity and costs.

Final Thoughts

Thin-walled extruded aluminum rectangular tubes are lightweight, affordable, and easy to process, making them suitable for low-pressure applications and cost-conscious projects.

However, their limited strength and welding challenges mean they are best suited for environments where heavy loads or high pressure are not a concern. Buyers should evaluate their specific needs before selecting this type of tube.

Learn more: Aluminum Tube Manufacturing and Bending Complete Guide