What is Triangular Aluminum Extrusions?

Triangular aluminum extrusions are profiles with a triangular shape made from aluminum alloys through the extrusion process. They are strong, stable, and versatile, so used in the construction, automotive, and aerospace industries. They support loads efficiently while being light.

This article will cover the features, benefits, and applications of aluminum triangular extrusions. We will also cover the process and how they can help your project. Whether you are an engineer, architect, or DIYer, understanding aluminum triangular extrusions will help you make the right choice for your next project.

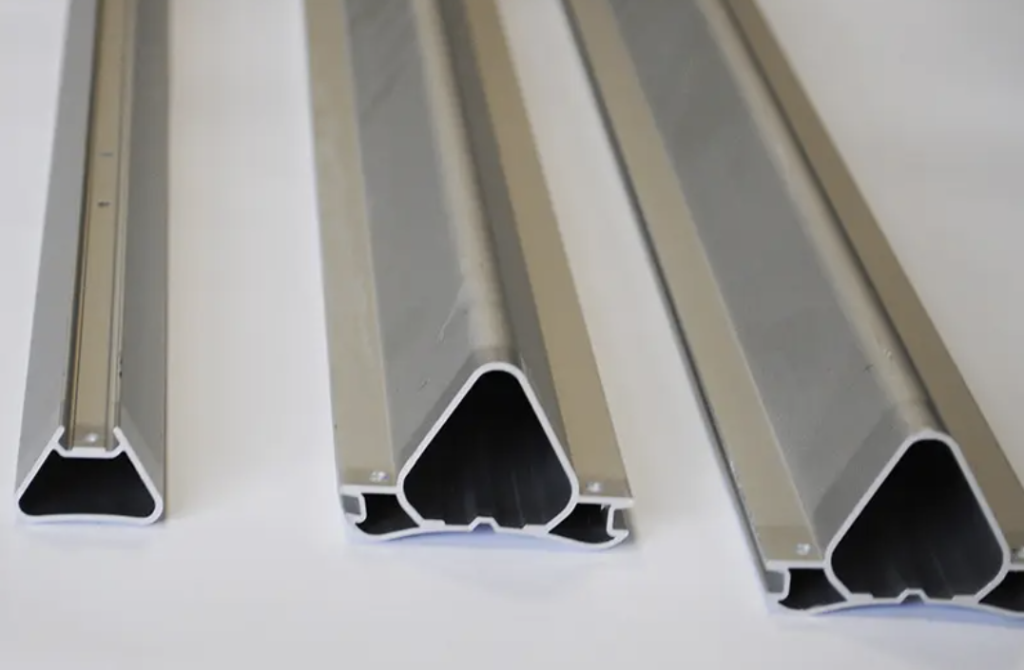

Triangular Extrusions Shape

Triangular extrusions have a triangular cross-section. This shape provides specific physical properties and structural strength, making it useful for various applications.

- Equilateral Triangle: An equilateral triangular aluminum extrusion has three sides of equal length. This design offers symmetry and stability, making it suitable for many structural needs.

- Unequal Triangle: An unequal triangular extrusion has three sides of different lengths. This profile can be customized to meet the specific requirements of a project, allowing for design flexibility.

Triangular aluminum extrusions are valued for their strength and versatility. Whether you need the stability of an equilateral design or the adaptability of an unequal shape, these profiles can meet diverse engineering demands.

Angle Classification

45-Degree Angle Aluminum

This aluminum type is commonly used for support or connections at a 45-degree angle. It provides stability and strength in various applications.

135-Degree Angle Aluminum

This aluminum is used for structures that require a 135-degree angle. It works well with 45-degree angle aluminum, offering versatile construction options.

Both angle types are important for creating strong frameworks. Whether you need precise connections or unique structures, these angles provide essential support.

Triangle Extrusion Size

Triangular profile extrusions have side lengths that range from 10 mm to 80 mm and thicknesses from 1 mm to 4 mm.

You can customize the length based on your project needs. This flexibility allows these extrusions to fit various applications effectively.

Features of Aluminum Triangle Profile

Triangular profiles combine strength, lightness, and style. They serve well in both structural and decorative applications, making them a versatile choice for various projects.

High Strength

Triangle-shaped extrusions provide a larger force area compared to standard aluminum under axial forces. This design results in higher load-bearing capacity and strength. The triangular shape also offers stable mechanical properties, preventing material deformation and fatigue.

Lightweight

The compact structure of triangular extrusions maximizes material utilization, making them relatively light. This quality is ideal for applications where reducing weight is essential, such as in aviation, automotive, and sports equipment.

Excellent Corrosion Resistance

Aluminum resists corrosion naturally, and triangular aluminum profiles enhance this property. Their surfaces can be oxidized, painted, or coated with protective films to improve corrosion resistance further.

Stylish Decorative Material

Triangular shapes enhance architectural designs, such as roofs and facades. The protruding triangles add a modern touch to buildings, increasing their aesthetic appeal and property value.

Applications of Triangle Extrusions

Aluminum triangular profiles play important roles in both functional and decorative applications. Their strength and versatility make them a preferred choice in many industries.

Building Materials

Aluminum Triangle extrusions are used in construction to create structural components like roofs, walls, and columns. Their high strength and excellent corrosion resistance make them ideal for various building projects.

Decorative Materials

These extrusions are also popular in decorative engineering. Their triangular cross-section and surface treatments provide visual appeal, enhancing the design of buildings and structures.

Production Process of Triangular Aluminum Extrusions

The production of triangular aluminum extrusions includes several key steps:

- Preparation of Materials: Choose suitable aluminum alloy materials. Cut and clean the materials.

- Heating: Heat the aluminum billet to a temperature that increases its plasticity.

- Extrusion: Insert the heated aluminum billet into the extruder. Apply pressure through the die cavity to shape it into a triangular cross-section.

- Cooling: Cool the extruded aluminum profile to enhance its hardness and strength.

- Subsequent Processing: Perform additional processes as needed, such as cutting, punching, and surface treatment.

This process transforms raw aluminum into strong triangular extrusions ready for various applications. Each step is essential for achieving high-quality results in the final product.

Final Thoughts

Triangular aluminum extrusions are stable and strong so they are useful in construction. They support various loads and are part of the structure. Used as beams, supports and decorative, triangular aluminum extrusions add functionality and aesthetics in modern engineering.

Hugh Aluminum manufactures aluminum extrusions. We design and produce different aluminum profiles to meet various needs.