What is Triangular Aluminum Extrusions?

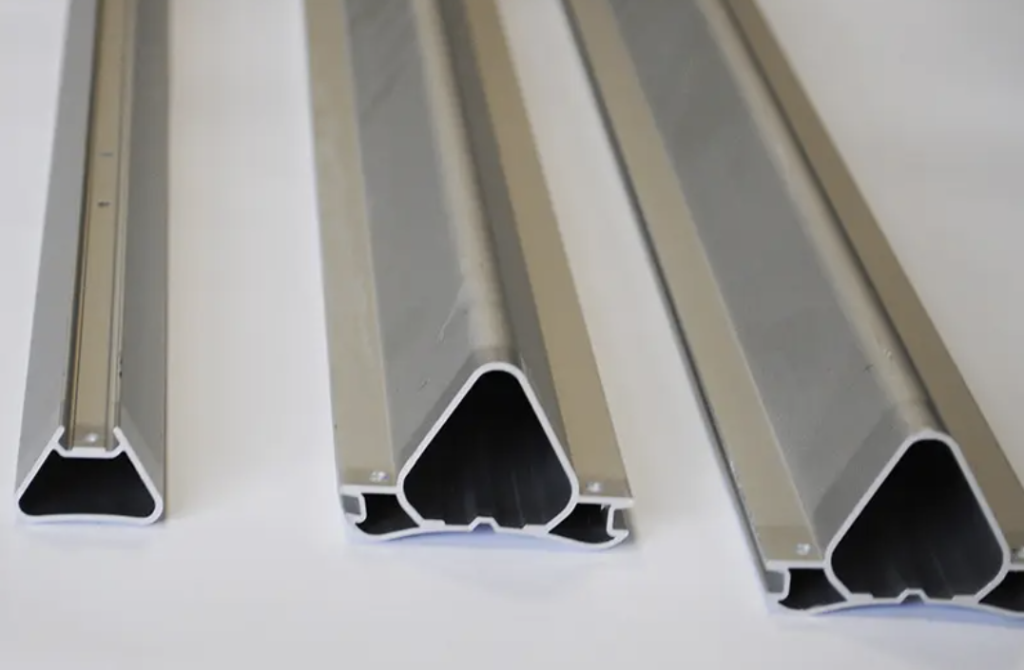

Triangular aluminum extrusion is a profile with a triangular cross-section made from aluminum alloy material by extrusion molding process.

It plays an important role in construction by virtue of its triangular stability.

Let’s learn what it really is today:

Its shape:

The shape of a triangular aluminum extrusion presents a triangular cross-section. This shape gives it unique physical properties and structural strength that give it advantages in certain applications.

1. Equilateral Triangle:

A triangular aluminum extrusion with three sides of equal length provides optimum symmetry and stability.

2. Unequal Triangular:

Triangular aluminum profiles where all three sides are unequal in length. This profile is usually customized according to the requirements of a specific project.

3. Angle classification:

- 45 Degree Angle Aluminum: Commonly used for support or connection at a specific angle.

- 135 Degree Angle Aluminum: Corresponding to 45 degree angle aluminum, it is used to build a structure at a specific angle

4. triangular aluminum extrusion size:

Its side length ranges from 10mm-80mm, its thickness from 1mm-4mm.

The length can be customized according to the project requirements.

So what characteristics does it have?

Features of triangular aluminum extrusion:

1. high strength:

The triangular aluminum extrusion has a larger force area than ordinary aluminum when axial force is applied, so it has higher load bearing capacity and strength. In addition, the triangular structure has stable mechanical properties, which can effectively prevent material deformation and fatigue damage.

2. Lightweight:

Due to the compact structure of the triangular aluminum extrusion, the material utilization rate is high, so the weight is relatively light. In occasions where weight reduction is required, such as aviation, automotive, sports equipment and other fields, triangular aluminum extrusion is a very ideal choice.

3. Excellent corrosion resistance:

Aluminum itself has good corrosion resistance, and triangular aluminum profiles are even more superior on this basis. Its surface can be oxidized, painted or covered with protective film to further enhance the corrosion resistance of the material.

4. Stylish decorative material:

Triangles can help complete some architectural designs, such as roofs or house facades. The protruding triangles make the building more aggressive and modern, and using it on a construction project can increase the value of the property.

applications of triangular aluminum:

1. Building materials: triangular aluminum extrusions are often used in building structures to make structural components such as roofs, walls and columns. Due to its high strength and excellent corrosion resistance, triangular aluminum profiles are widely used in construction projects.

2. Decorative materials: They are also widely used in the field of decorative engineering. Its unique triangular cross-section and surface treatment make it have high decorative value and visual effect.

Production process

The production of triangular aluminum extrusion mainly includes the following steps:

1. Preparation of materials: choose suitable aluminum alloy materials and carry out pre-treatment, such as cutting and cleaning.

2. Heating: Heat the aluminum billet to a temperature suitable for extrusion to improve the plasticity of the material.

3. Extrusion: Put the heated aluminum billet into the extruder and apply pressure through the die cavity to make it deform plastically and form a triangular cross-section.

4. Cooling: The extruded aluminum profile is cooled to improve its hardness and strength.

5. Subsequent processing: subsequent processing such as cutting, punching, surface treatment, etc. are carried out as required.

Final Summary

Triangular aluminum extrusion is a material with triangular cross-section made by aluminum extrusion molding process. It has a stable shape, excellent material and a wide range of applications.

Hugh Aluminum is a aluminum extrusion manufacturer. We design and manufacture all types of aluminum profile.

If you need to purchase aluminum products in bulk or looking for aluminium suppliers?

Please contact us! We have 14 years of manufacturing experience and served more than 600+ customers from 40+ countries. Our team is friendly and professional.

Please contact us!