Which Process is Cheapest for Manufacturing Aluminum Round Tubes?

When manufacturing aluminum round tubes, cost plays a significant role in choosing the right process. Two main methods are commonly used: extrusion molding and welding. Let’s compare these processes to determine which one is more cost-effective.

Related products: Extruded aluminum tubes

Extrusion Molding Process

Raw Material Cost

The extrusion process uses aluminum ingots or alloys as raw materials. These materials are cost-efficient because extrusion achieves high material utilization, reducing waste.

Production Costs

Extrusion involves heating the material, forming it through a die, cooling it, and performing secondary processing. While the initial investment in extrusion equipment is high, the cost per unit decreases as production scales up.

This method is efficient, lowering labor costs and reducing equipment depreciation per unit. It is considered the most economical option for mass production.

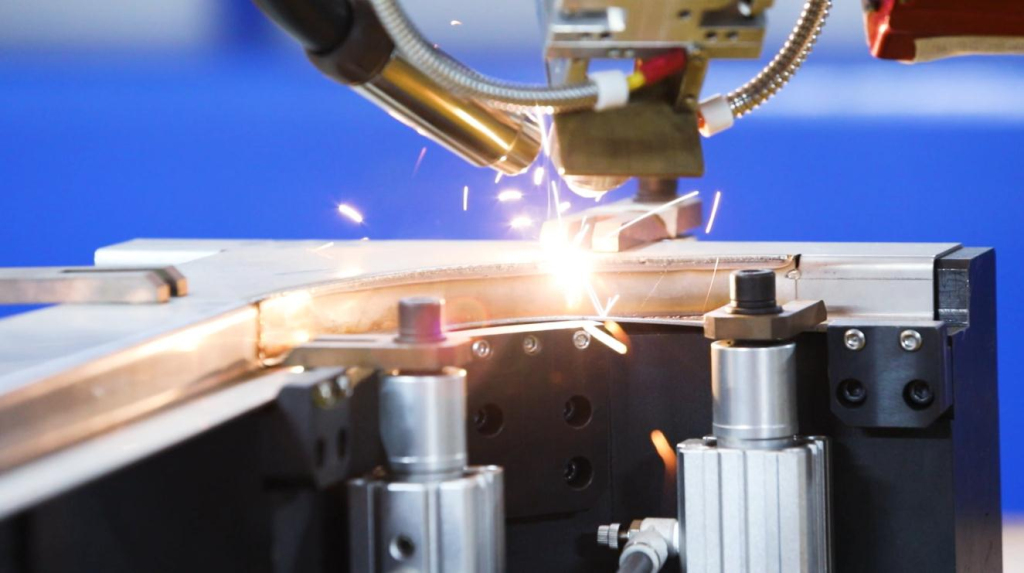

Welding Process

Raw Material Cost

Welding uses prefabricated aluminum sheets or shapes as raw materials. While the material cost is similar to extrusion, welding generates more scrap, making it less efficient in material usage.

Production Costs

Welding includes cutting, welding, grinding, and treating aluminum. This process requires skilled labor and precise operations, increasing labor costs. Each tube requires individual welding, which slows production and raises costs compared to extrusion.

Final Comparison Table

| Feature | Extrusion Molding | Welding |

|---|---|---|

| Raw Material Cost | Lower: High material utilization | Higher: More scrap generated |

| Production Costs | Lower: High efficiency and reduced labor costs | Higher: Labor-intensive with slower production |

| Equipment Investment | Higher upfront but cost-effective long-term | Moderate but less efficient overall |

| Best Use Case | Mass production with consistent quality | Small-scale or custom applications |

Conclusion

The extrusion molding process is generally the cheapest option for manufacturing aluminum round tubes. It offers lower material and production costs while maintaining high efficiency and consistent quality. For large-scale production, extrusion is the clear winner in terms of cost-effectiveness.

If you are considering small-scale or custom applications where precision is key, welding may still be a viable option despite its higher costs.

Learn more: Aluminum Tube Manufacturing and Bending Complete Guide