Why Aluminum Heat Sinks Are Necessary?

Heat management is key to device performance and longevity. As components heat up when in use, we need to dissipate that heat quickly to avoid overheating. Aluminum heat sinks are the answer.

Aluminum heat sinks are used in many applications from computers to industrial machines. They are light and have good thermal conductivity. But why aluminum for heat sinks? Let’s explore the importance of aluminum heat sinks.

How Does a Heat Sink Work?

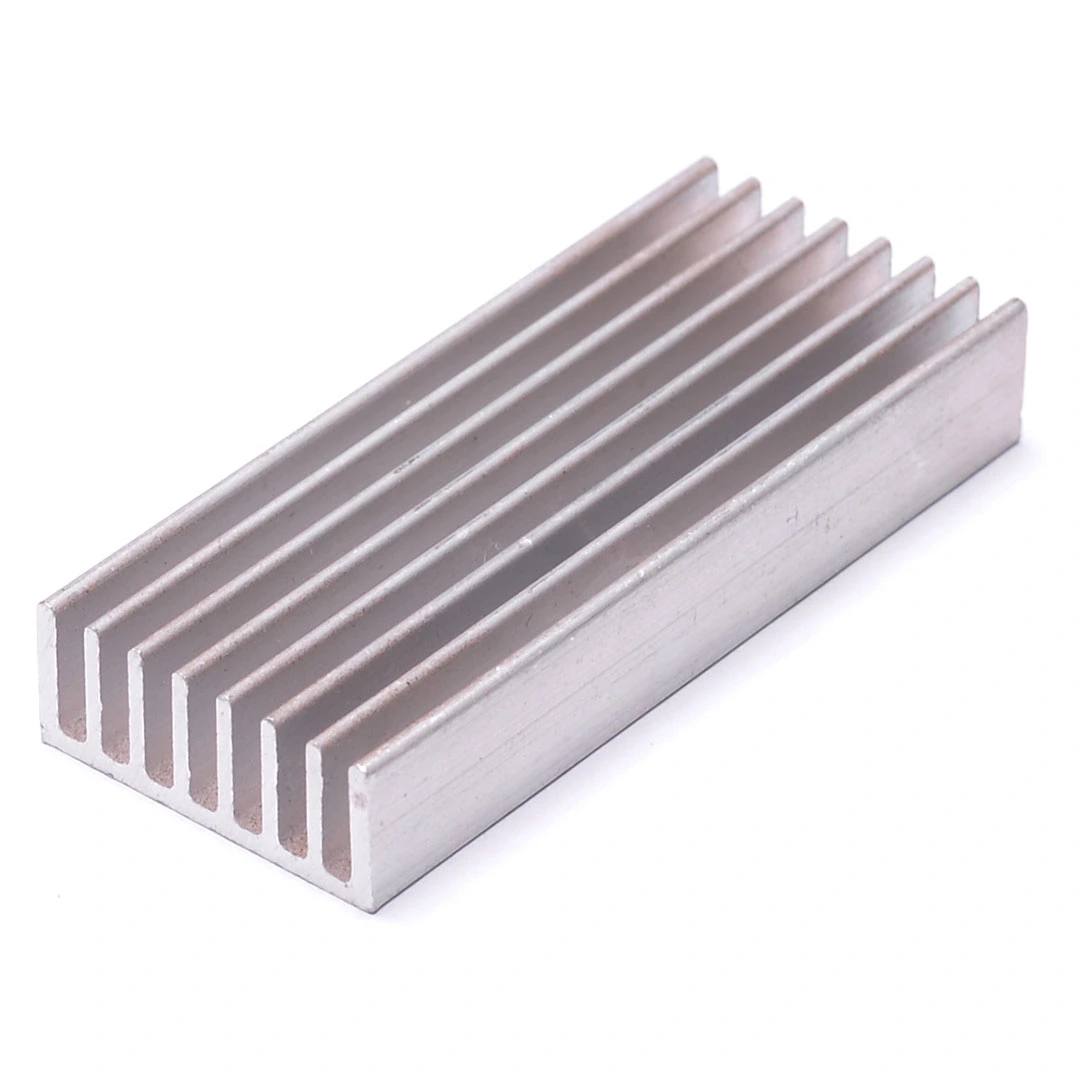

A heat sink directs heat away from hot devices. It increases the surface area available for heat transfer. The larger the surface area, the more heat can escape into the surrounding air.

For a heat sink to function effectively, it must be at a higher temperature than its environment. This temperature difference allows heat to flow from the device into the heat sink and then into the air. By maintaining this flow, heat sinks help keep electronic components cool and operating efficiently.

Read more: A Complete Guide to Heat Sink for Cooling

Why Aluminum Heat Sinks Are Important?

Heat sinks are typically made of metal, with copper and aluminum being the most common choices. Both types help electronic devices operate at higher temperatures and extend their lifespan. However, aluminum heat sinks stand out for several reasons:

Lightweight

Aluminum is lighter than other metals, making it easier to handle. This lightweight nature simplifies processing and transportation. Using aluminum in large heat sinks significantly reduces overall weight, lowering production costs and making installation easier.

Good Thermal Conductivity

Aluminum has excellent thermal conductivity. It effectively transfers heat to the cooling fins, allowing for quick heat dissipation. Compared to other materials, aluminum excels in both heat dissipation and conduction.

Easy to Process

Aluminum heat sinks are easy to shape and process. Manufacturers can extrude aluminum into various profiles to create different designs. Shapes like round, hollow, fluted, and more can be achieved through specialized molds. Additional methods like stamping and CNC machining allow for more complex designs.

Low Cost

Aluminum heat sinks are more affordable than those made from materials like copper or ceramic. Aluminum is abundant and easier to mine than many metals. This affordability makes aluminum the preferred choice for most heat sinks, especially since processed aluminum requires minimal maintenance.

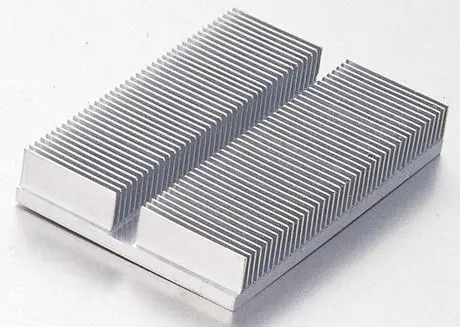

Diverse Shapes

The extrusion process allows aluminum heat sinks to be designed in many shapes. This flexibility meets design needs that other metals may not fulfill. For instance, complex servers or AI computer heat sinks often rely on extruded aluminum to manage temperatures effectively.

Fully Recyclable

Over time, heat sinks may become damaged or corroded and need replacement. Unlike zinc or copper, which can produce toxic pollutants during recycling, aluminum is fully recyclable. Even aluminum alloys can be recycled and transformed into new products without losing quality.

Conclusions

Aluminum heat sinks offer several advantages: low cost, lightweight design, high thermal conductivity, ease of processing, and versatility in shape. As demand for electronic components grows, the market for aluminum heat sinks will likely expand further, attracting more consumers looking for efficient cooling solutions.

Hugh Aluminum – A Reliable Heatsink Supplier

Now that you understand the importance of aluminum heat sinks, how do you find the right one? Hugh Aluminum can help. We offer a variety of extruded aluminum heat sinks to meet your needs. As an experienced aluminum extrusion manufacturer, we have supplied major companies like Huawei, Asus, and HTC. Our customers consistently recognize the quality of our products.

If you are looking to purchase heat sinks, contact our team! We are ready to help you find the perfect solution for your project.