Why are aluminium extrusions difficult to corrode?

Aluminium extrusions are basically difficult to corrode. Its normal use life can be up to ten years or more. Why does it resist corrosion? Let’s analyse its ability today.

Its corrosion resistance is mainly reflected in the following aspects:

1. Naturally formed aluminium oxide film:

Aluminium extrusions naturally react with oxygen in the air to form a dense aluminium oxide film. This film is the basis for the corrosion resistance of aluminium profiles.

This oxide film not only covers evenly, but also has high hardness and quality. It can effectively prevent further erosion of aluminium by moisture, oxygen and other corrosive media.

2. Self-repairing ability of the oxide film:

Aluminium alloy oxide film formed in the air has the ability of self-repair. It can constantly repair the damage caused by external factors and maintain its integrity. This ensures the long-term corrosion resistance of aluminium.

3. Testing of aluminium extrusions corrosion resistance:

Our common construction Aluminium extrusions will undergo strict testing before leaving the factory. Including salt spray test and drip alkali test etc. to test its corrosion resistance. So the use of its corrosion resistance is guaranteed.

Salt spray test mainly examines the acid resistance of aluminum extrusions. The alkali drop test mainly examines its alkali resistance. These testing methods can comprehensively assess the corrosion resistance of aluminium profiles in different environments.

4. Purity of aluminium extrusions:

The corrosion resistance of aluminium products is closely related to their purity. Pure aluminium has the best corrosion resistance because it does not contain impurities that reduce corrosion resistance, e.g. iron, copper, etc. o Industrial aluminium profiles usually have a high corrosion resistance.

Nevertheless, its corrosion resistance can be improved by other processes. For example, heat treatment after aluminium extrusion. Therefore it will have better corrosion resistance.

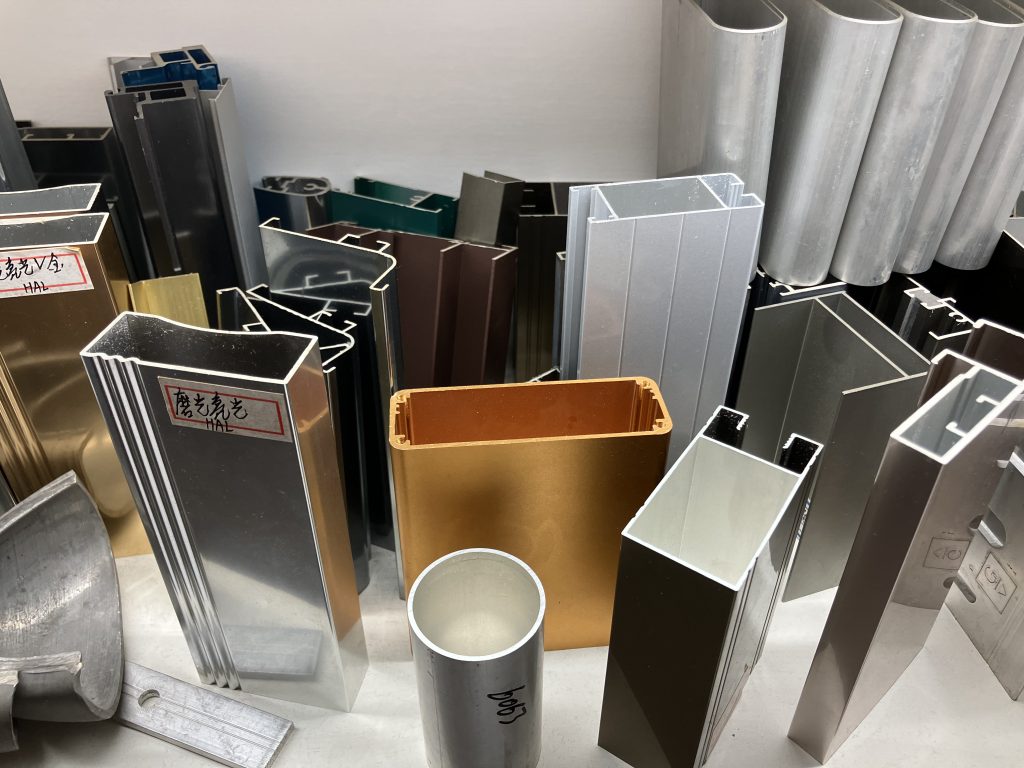

5. Anodising and powder coating:

We can do it by anodising treatment. It will form a thicker and denser oxide film on the surface of aluminium extrusions, which will further improve the corrosion resistance of aluminium extrusions.

In addition, we can also use powder coating process. Increase the coating on its surface to achieve the protective effect. These surface treatments can increase the corrosion resistance of Aluminium extrusions by about 40%.

In summary

Aluminium extrusions are very difficult to corrode. This is because it has an aluminium oxide film, the self-repairing ability of the oxide film, and electrochemical properties. These characteristics make it resistant to corrosion.

In addition, we can increase its resistance to corrosion through testing and surface treatment at the manufacturing plant.

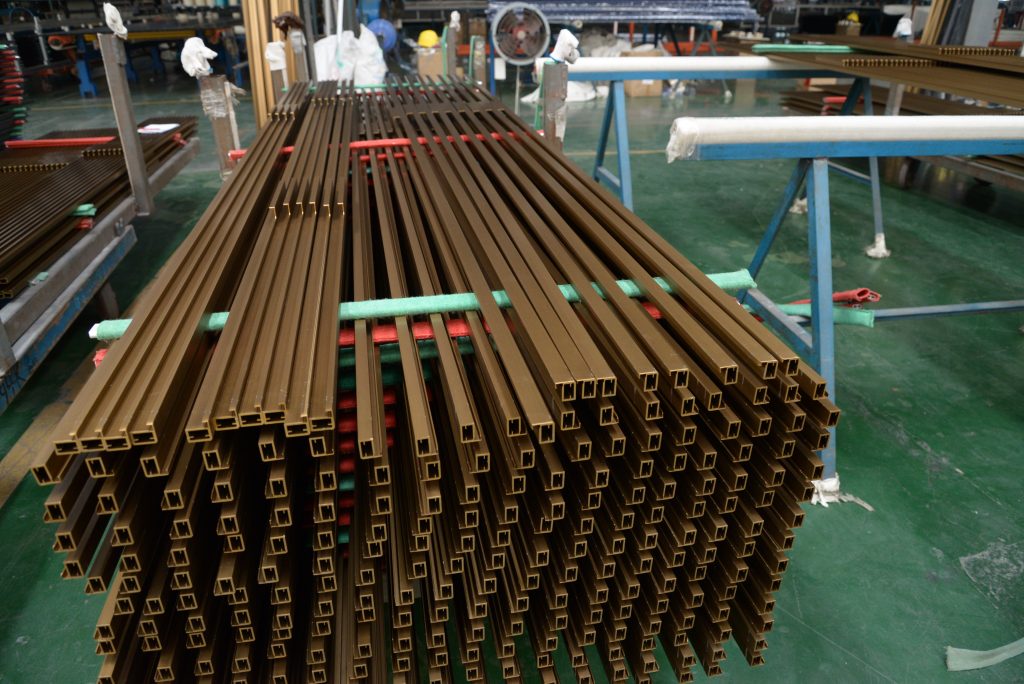

Hugh Aluminum is an aluminium extrusion factory located in China. We have 14 years of manufacturing experience and have served more than 600 customers from 40 countries.

If you want to purchase aluminium products in bulk or looking for aluminium suppliers?

Please contact us! Our team is professional and full of friendly.