Why Heat Sinks are made of aluminum

In 2023 with the development of AI technology. Building servers are springing up all over the world to train AI, so heatsinks have been increasing in market demand in recent years. People have started asking why heatsinks are overwhelmingly made of aluminum?

Let’s find the answer today.

1. Aluminum has good thermal conductivity

Aluminum has a thermal conductivity of 167 W/m.K, while steel has a thermal conductivity of 70 W/m.K. Although the metals copper and silver are superior to aluminum in terms of thermal performance. The thermal conductivity of pure copper is 401 W/(m-K) and that of pure aluminum is 237 W/m-K. But the cost of a copper heat sink is four times that of an aluminum heat sink. Therefore, the thermal conductivity of aluminum is excellent in terms of heat dissipation performance.

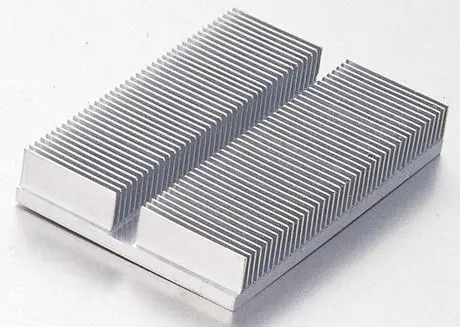

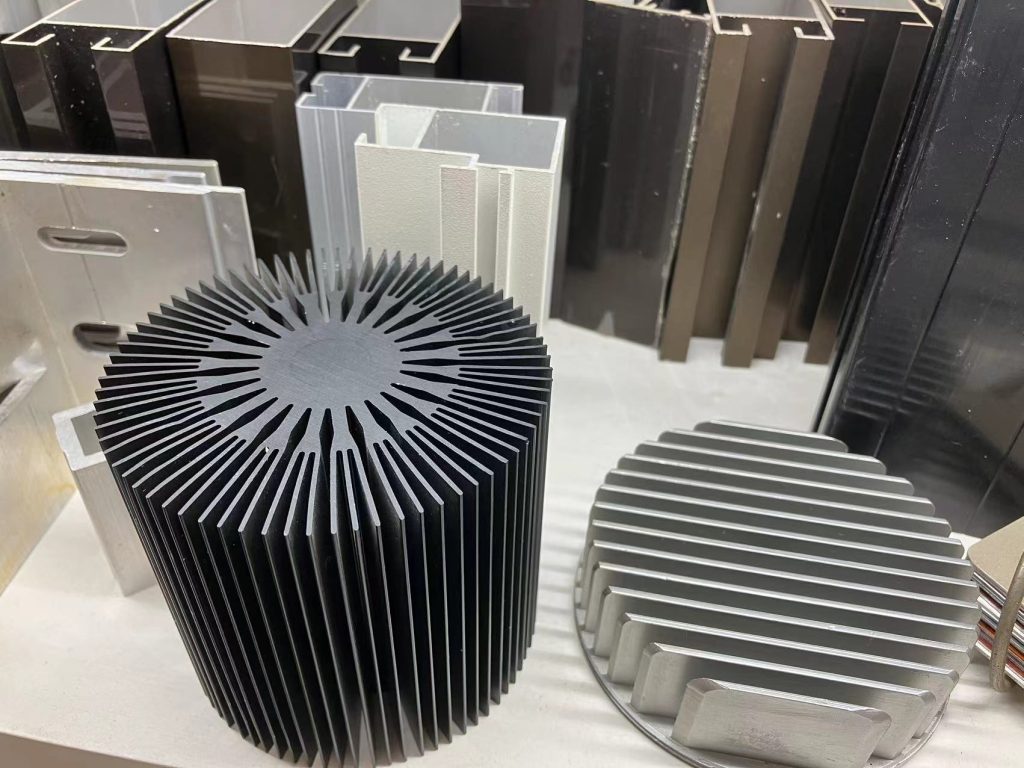

2. Aluminum is less dense and less difficult to process.

The density of aluminum is 2.7g/cm^3, which is 1/3 of the density of copper. This means that a large heatsink, such as a street lamp or charging heatsink, can be made. Copper heatsinks are more difficult to process and are heavier. Aluminum is more suitable in terms of cost, and aluminum heatsinks are obtained by extruding aluminum. The simplicity of processing and low manufacturing costs allow it to dominate the heatsink market.

3. High specific heat capacity of aluminum

Aluminum has a high specific heat capacity, which is also an important parameter for heat sinks, but it is often overlooked. A medium with a high specific heat capacity will absorb or emit more heat when it rises or falls by 1 degree Celsius. The specific heat capacity of copper is 386KJ/kg-K, while that of aluminum is 900KJ/kg-K, almost three times that of copper. This means that aluminum heat sinks can continuously carry heat to other places, whereas copper cannot.

4. Price

Aluminum heat sinks are obtained by processing aluminum profiles. Because of the material characteristics of aluminum profiles, it is easy to be surface-treated and CNC-machined. Therefore, aluminum heatsinks are much cheaper to manufacture than copper and ceramic heatsinks. For high performance heatsinks, it is often necessary to drill holes in the heatsink and CNC process it to achieve better heat dissipation. Aluminum heatsinks undoubtedly meet these conditions.

Summarize

Why don’t you choose aluminum instead of other materials for heat sinks. It is because of its low cost, low processing difficulty, high specific heat capacity, excellent thermal performance and light weight. All these features meet the working requirements of heat sinks, so that aluminum heat sinks occupy the vast majority of the heat sink market.

Hugh Aluminum is an aluminum extrusion manufacturer based in China. We manufacture aluminum profile products including aluminum PCB heat sink,aluminum heat sink, aluminum LED heat sink, aluminum deck, aluminum fence, aluminum doors and windows, solar aluminum frame. We offer large quantity of aluminum building materials and factory price.